Abstract

Herbal injection is one of the most important preparations of traditional Chinese medicine. More than 130 types of herbal injections are used clinically for 400 million patients annually with total sales of over four billion US dollars per year. However, the current quality control (QC) methods relying mainly on chemical fingerprints (CF) can hardly ensure quality and safety of the herbal injections with complex chemical composition and have resulted in an increase in serious adverse drug reactions. In this study, a comprehensive approach for the QC of a controversial herbal injection Shuang-Huang-Lian lyophilized powder (SHL) was established based on the quality fluctuation detection by a combination of CF and biological fingerprint (BF). High-performance liquid chromatography and the impedance-based xCELLigence system were applied to establish the CF and BF, respectively. In addition, multivariate analysis was performed to evaluate the discriminant ability of the two methods. The results showed that being subjected to environmental influence like oxygen/air, high temperature, and extreme illumination could lead to quality fluctuation of SHL. The combination of chemical and biological fingerprint method is a more powerful tool for the QC of SHL because it can clearly discriminate different groups of abnormal samples. This method can be used for the detection of quality fluctuation of SHL and can provide reference for the quality control of other herbal injections.

Similar content being viewed by others

Introduction

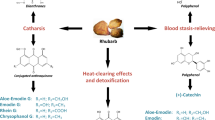

Herbal injections are an important innovation of the modernization of traditional Chinese medicine. They have been extensively researched by pharmaceutical companies and research institutes from China, USA, and Germany, owing to their rapid and powerful therapeutic effects [1–3]. More than 130 types of herbal injections are used in clinical disease treatment for about 400 million patients annually with total sales of over 4 billion US dollars per year [4]. In the prevention and control of severe acute respiratory syndrome (SARS) in 2003 and pandemic influenza H1N1 in 2009, herbal injections like Shuang-Huang-Lian (SHL) and Qing-Kai-Ling contributed greatly and received widespread attention [5, 6]. However, this powerful formulation still cannot be accepted internationally because of its complicated quality control (QC) procedures and the high number of serious adverse reports [7–10].

Because most herbal injections consist of several medicinal plants and their chemical composition is complex, their clinical efficacy and safety are affected by various factors. These variables include differences in patient characteristics, improper use, and substandard drug quality. However, substandard drug quality is regarded as the most important factor accounting for the increase in adverse reactions [7, 10]. Quality fluctuation and batch-to-batch variability have long been a problem for the QC of herbal injections and other herbal products for a long time [4, 11]. Spectroscopic-based chemical fingerprint (CF) and assaying of multiple ingredients have played an important role in the QC of herbal injections in the past decades. With the development of more advanced analytical methods, more constituents can be detected, and the QC of the herbal injections has been greatly improved [12–15]. Nevertheless, there are still many substances that cannot be detected because of the relative lack of absorption in spectra [16, 17]. Meanwhile, the spectrum-based method cannot be associated with clinical efficacy or adverse reactions. All these have made it difficult to ensure the consistently good quality of herbal injections, and have somehow resulted in an increase of adverse reactions. Therefore, it is imperative to develop a more sensitive and specific method for the QC of herbal injections [18].

Quality control methods based on biological profiles have been demonstrated to be sensitive and specific, and can provide “fingerprint” characteristic information [19, 20]. Because the various ingredients of intravenous herbal injections may affect target cells immediately, cell-based in vitro assays are considered to be efficient and sensitive to providing early predictions about the biological activity of herbal injections. Herein, we used a real-time and quantitative bioanalytical method named xCELLigence system to establish a biological fingerprint (BF) for the QC of herbal injections. This technique is based on the continuous monitoring of cellular responses in real time, which produces specific time-dependent cell response profiles (TCRPs). Compounds with different biological activities often produce different TCRPs [21–23]. Therefore, we propose that this TCRP-based method can be helpful to validate the consistency and stability of herbal injections.

In this study, a feasible approach for the QC of herbal injections was established based on the quality fluctuation detection by a combination of CF and BF (Fig. 1). SHL lyophilized powder, an herbal injection which has been widely reported to cause adverse reactions, was chosen as the model drug. Seven batches of normal samples and 21 batches of artificial abnormal samples of SHL were collected to establish CF, and their effect on mast cell line RBL-2H3 was monitored to establish the BF. The results were analyzed by multivariate statistical analysis. Our study could provide a new insight into the QC of SHL and other herbal injections with complex chemical components. The experimental strategy used in this study is shown in Fig. 1.

Experimental

Reagents and materials

Chromatographic-grade acetonitrile was purchased from Fisher Chemicals (Pittsburg, PA, USA). All other chemicals were of analytical grade and purchased from Beijing Chemical Reagent Co. (Beijing, China). Ultrapure water was obtained from a Milli-Q Water Purification System (Millipore, Bedford, MA, USA). Reference substances (chlorogenic acid, neochlorogenic acid, cryptochlorogenic acid, caffeic acid, isochlorogenic acids A, B, and C, forsythoside A, baicalin, baicalein) were supplied by Chengdu Must Bio-Technology (Chengdu, China, purity ≥ 98 %). Compound 48/80 was purchased from Sigma Chemical Co. (St. Louis, MO, USA).

Dulbecco’s modified Eagle medium (DMEM), Pen/Strep (10,000 units mL−1 penicillin, 10,000 μg mL−1 streptomycin), 0.25 % trypsin-EDTA, fetal bovine serum (FBS) were purchased from Gibco (Grand Island, NY, USA).

Preparation of samples

Seven batches of normal SHL samples were from Harbin Pharmaceutical Group Co., Ltd. (Harbin, China). To magnify and expose the data on quality fluctuation, 21 batches of artificial abnormal samples were prepared according to the quality influencing factors such as: extreme illumination, high temperature, and exposure to air. Therefore, four groups of samples were prepared: NS1–NS7 (normal samples; samples were kept at room temperature away from light), TS1–TS7 (high-temperature accelerated samples; kept NS1–NS7 in a 60 °C calorstat for 10 days), LS1–LS7 (extreme illumination accelerated samples; kept NS1–NS7 under 1 × 104 lx illumination for 10 days), and ES1–ES7 (samples exposed to the environment; opened the ampoules of NS1–NS7 and kept them at room temperature away from light for 10 days). Detailed information about the samples is listed in Table S1, Electronic Supplementary Material.

CF assay

Preparation of standard and sample solutions

Standard solutions (chlorogenic acid, neochlorogenic acid, cryptochlorogenic acid, caffeic acid, isochlorogenic acids A, B, and C, forsythoside A, baicalin, baicalein) were prepared by dissolving an accurately weighed amount of each standard substance in 50 % methanol in a volumetric flask.

The sample solutions were prepared according to the above procedure. The dried powders of SHL samples were accurately weighed into a clean volumetric flask, and then dissolved in a certain volume of 50 % methanol. The standard and sample solutions were subsequently filtered through a 0.22 μm membrane filter (Xinya, Shanghai, China) for analysis.

Apparatus and chromatographic conditions

CF analysis of SHL was performed on a Waters Alliance 2695 (Milford, MA, USA) equipped with a quaternary pump, vacuum degasser, autosampler, and a Waters 996 photodiode array (PDA) detector.

The chromatographic separation was carried out using a Phenomenex Luna-C18 (2) column (4.6 × 250 mm; 5 μm), operated at 40 °C. A gradient consisting of solvent A (water/phosphoric acid, 100:0.5, v/v) and solvent B (acetonitrile) was applied at a flow rate of 1.0 mL min−1 as follows: 5 % B isocratic from 0 to 5 min, 5–10 % B linear from 5 to 15 min, 10–14 % B linear from 15 to 20 min, 14–18 % B linear from 20 to 50 min, 18–25 % B linear from 50 to 70 min, 25–30 % B linear from 70 to 85 min, 30–50 % B linear from 85 to 110 min. The sample injection volume was 10 μL. The re-equilibration time of the column was 10 min. The detection wavelength was set at 350 nm. Spectral resolution was set at 1.2 nm (the highest resolution possible), and the recording frequency was one spectrum per second. The CF of each sample was recorded in triplicate and the mean values were calculated and used for the analysis.

Similarity analysis of CF

A professional similarity evaluation system named Similarity Evaluation System for Chromatographic Fingerprint of Traditional Chinese Medicine (Chinese Pharmacopoeia Committee, Version 2004 A) was used to evaluate the stability of the normal samples and the potential variation of chemical constituents of the abnormal samples. The representative standard chemical fingerprint (RSCF) was generated by using the mean value of seven batches of normal samples, and common peaks were defined. The relative peak area of common peaks was calculated and the similarity of all samples was generated by comparing with the RSCF.

BF assay

Cell culture

RBL-2H3, a cell line which has been extensively used as a mast cell model to study anaphylaxis and anaphylactoid reactions was selected as the model cell [24]. The cells were obtained from Shanghai Institute of Cell Biology, Chinese Academy of Science (Shanghai, China). The cells were cultured in a standard humidified incubator at 37 °C and 5 % CO2 using DMEM, supplemented with 15 % FBS, 100 units mL−1 penicillin and 100 μg mL−1 streptomycin. After reaching confluence, the cells were washed with PBS, then detached by 0.25 % trypsin-EDTA and diluted to the seeding concentration.

Apparatus and cell treatment

The impedance-based BF assay was performed using the xCELLigence Real-Time Cell Analyzer (RTCA) DP instrument (ACEA Biosciences, San Diego, CA, USA). The instrument consists of a RTCA DP Analyzer and the RTCA Control Unit 1.1. The RTCA DP Analyzer was placed inside a standard CO2 incubator and used to connect with up to three different 16-well E-plates. The cellular responses were monitored and expressed as a dimensionless parameter called cell index (CI).

After the measurement of background impedance, 2.5 × 104 cells in 100 μL medium were seeded into the E-plates and the CI value was continuously recorded. After the 24-h growth period, the 200 μL of spent medium was removed and cells were gently washed by fresh culture medium. Then, different batches of SHL samples (200 μL) at a concentration of 0.8 mg mL−1 in the culture medium were added to cells, and the CI was measured automatically once per minute until the end of the experiment to obtain the TCRPs. Meanwhile, compound 48/80 (C48/80) at a concentration of 30 μg mL−1 was applied throughout this study as the control sample to verify valid performance of the cell system.

Analysis of BF

According to the similarity evaluation of the CF, a representative standard biological fingerprint (RSBF) was generated by taking the mean value of the seven batches of normal samples. The similarity of all samples with the RSBF was then calculated. Meanwhile, the inhibition ratio of SHL on RBL-2H3 after 12 and 24 h (I 1, I 2), the time needed for cell desorption from the plate after drug addition (ΔT), and the area under the real-time cell response curves (AUC) were calculated for further analysis [25–27].

Statistical analysis

In the present study, hierarchical cluster analysis (HCA) and principal component analysis (PCA) were used to sort samples into groups and obtain an overview of variation between different groups. HCA was performed using IBM SPSS Statistics 20 software (IBM Corporation, Armonk, NY, USA) and PCA was performed using SIMCA-P software (version 11.5, Umetrics, Umeå, Sweden). For HCA, the between-group linkage method was used as the clustering algorithm, and the squared Euclidean distance was selected as measurement.

Results

CF analysis of SHL

Method validation

To obtain a stable and repeatable CF for the quality control of SHL, a method validation of the HPLC fingerprint analyses was conducted based on the retention time and peak area. The method precision was assessed by six replicate measurements of a random selected sample (NS3). The relative standard deviations (RSD) values of retention times and peak areas of all peaks were <2 % and <3 %, respectively. The repeatability of the method was assessed by analyzing six different sample solutions independently prepared from the same sample (NS3). The stability was evaluated by analyzing the same sample (NS3) at 0, 2, 4, 6, 8, and 24 h after solution preparation. The RSD of the peak areas was <3 %. This indicated that the sample solution of SHL was stable within 24 h. Linearities for the identified components were also established and the calibration curves showed good linearity within test ranges (Table S2, Electronic Supplementary Material). All results indicated that the method of HPLC fingerprint analysis was reliable and satisfactory. The HPLC fingerprints of SHL were obtained under optimized conditions.

Similarity analysis

The RSCF was generated from seven batches of normal SHL samples (Fig. 2). Peaks, which existed in all chromatograms of the samples and presented stably, with large areas and good segregation from consecutive peaks, were regarded as common peaks. Furthermore, the area sum of all the common peaks must be more than 90 % of the total area of all the observed peaks in the chromatograms [28, 29]. Herein, 21 peaks (which contributed to more than 98 % of the total peak area and existed in each chromatogram of the normal samples) were defined as the common characteristic peaks. Ten constituents present in normal and abnormal samples (neochlorogenic acid, chlorogenic acid, cryptochlorogenic acid, caffeic acid, forsythoside A, isochlorogenic acids B, A, and C, baicalin, and baicalein) were identified by comparing the chromatographic peaks in sample fingerprints with standard substances at the same retention time. As shown in Fig. 3, the number of common peaks of the normal and 21 batches of abnormal samples decreased to 16 (peak no. 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, f, g, h, i, j, k). Peak 9 (baicalin), a common peak which existed in all chromatograms and presented stably with maximum content, was chosen as the internal reference substance. The relative retention time (RRT) and relative peak area (RPA) of common peaks in the standard chromatogram and the samples were recalculated, the data were shown in Table S3 and Table S4, Electronic Supplementary Material.

Reference standard chromatographic fingerprint from seven batches of normal Shuang-Huang-Lian samples. Ten peaks were identified and labeled with consecutive numbers while the unidentified peaks were labeled with small letters. Ten peaks were identified and labeled with consecutive numbers while the unidentified peaks were labeled with small letters. 1 neochlorogenic acid; 2 chlorogenic acid; 3 cryptochlorogenic acid; 4 caffeic acid; 5 forsythoside A; 6 isochlorogenic acid B; 7 isochlorogenic acid A; 8 isochlorogenic acid C; 9 baicalin; 10 baicalein

HPLC fingerprints of normal and abnormal samples of Shuang-Huang-Lian lyophilized powder. Characteristic changes in composition of the abnormal samples were marked with red dotted circles. R reference standard chromatographic fingerprint; NS normal samples; TS high-temperature accelerated samples; LS extreme illumination accelerated samples; ES samples exposed to the environment

The similarities between the fingerprints of 28 batches of samples and the RSCF were analyzed using the professional similarity evaluation system mentioned above. The results showed that compared with the RSCF, the fingerprints of samples from groups of NS and ES had relatively high similarities (>0.97), while the similarities of the fingerprints of samples from groups of LS and TS were irregular (0.85–0.97). Therefore, the samples from different groups could not be effectively distinguished by the similarity analysis alone.

Results of statistical analysis

In this study, each batch of the samples was analyzed by HPLC three times under the optimized conditions and the average values of the relative peak area (Table S3, Electronic Supplementary Material) were used for further statistical analysis. PCA and HCA were applied to evaluate the discriminating power of CF. Both the PCA scores plot (Fig. 4a) and HCA dendrogram (Fig. 5a) showed that the 28 samples of SHL could be classified into three groups. The high-temperature and extreme illumination accelerated samples could be clearly discriminated as abnormal samples while the samples exposed to the environment could not be distinguished from the normal samples.

Scores plots of principal component analysis (PCA) of the 28 batches of Shuang-Huang-Lian samples. a PCA was carried out using the peak area of the common peaks of the chemical fingerprints; b PCA was performed using the parameters derived from the biological fingerprints. NS normal samples; TS high-temperature accelerated samples; LS extreme illumination accelerated samples; ES samples exposed to the environment; PC1 principal component 1; PC2 principal component 2

Dendrograms of the hierarchical cluster analysis (HCA) for the 28 batches of Shuang-Huang-Lian samples. The between-groups linkage method was used as the clustering algorithm, and the squared Euclidean distance was selected as measurement. a HCA was carried out using the peak area of the common peaks of the chemical fingerprints; b HCA was performed using the parameters derived from the biological fingerprints. NS normal samples; TS high-temperature accelerated samples; LS extreme illumination accelerated samples; ES samples exposed to the environment

BF analysis of SHL

Method validation

To evaluate the reliability and accuracy of the impedance-based xCELLigence system, C48/80 and sample NS3 was chosen randomly and detected in different wells simultaneously. The RSD of parameters ΔT and AUC from each channel were both <3 %, indicating good homogeneity among different wells of the plates. According to the method validation of CF, the precision and repeatability of this method were assessed, and the RSD of the parameters were <3 % as well. The results indicated that this method for BF of SHL was reliable and satisfactory.

BF and parameter extraction

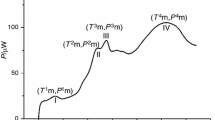

The BF of the 28 batches of SHL samples was generated using the impedance-based xCELLigence system. As cells interacting with these samples, continuous CI changes resulting from changes of cell number, morphology, and adhesion on the microelectrodes were measured by the RTCA DP instrument and the TCRPs were recorded (Fig. 6). For comparison, the RSBF was generated by taking the mean value of the seven batches of normal samples and was added to the BF of three groups of abnormal samples. As depicted in Fig. 6, significant difference could be observed visually between the BF of the normal and abnormal samples. The effect of LS and ES on the cells might be stronger than that of normal samples and NS.

Biological fingerprints of Shuang-Huang-Lian samples. RBL-2H3 cells were treated with same concentration of NS (a), TS (b), LS (c), ES (d) and 30 μg mL−1 compound 48/80 (C48/80). The real-time cell response curves were recorded by the xCELLigence system. NS normal samples; TS high-temperature accelerated samples; LS extreme illumination accelerated samples; ES samples exposed to the environment; RSBF reference standard biological fingerprint

To further analyze the BF of the samples, the similarities between the fingerprints of 28 batches of samples and the RSBF were calculated. The similarity values of the samples from groups of NS, TS, LS, and ES were in the range of 0.97–0.99, 0.91–0.93, 0.93–0.96, and 0.81–0.86, respectively. The other four parameters mentioned above (I 1, I 2, ΔT, AUC) were also calculated (Table S5, Electronic Supplementary Material).

Results of statistical analysis

To evaluate the discriminating power of BF and to further observe the similarities and differences among the different groups of samples, the five parameters of the BF (Table S5, Electronic Supplementary Material) were also submitted to the two statistical analysis methods. Both the PCA scores plot (Fig. 4b) and HCA dendrogram (Fig. 5b) showed that all the samples are clearly classified into four classes corresponding to the four groups of samples. Based on Eigenvalues >1, two principal components were considered significant, and the equations were as follows:

It could be concluded that I 1 and I 2 contributed more to the principle components, and they were the main parameters to classify the samples into four classes corresponding to the four groups.

Discussion

CF analysis has long been used for the QC of herbal products with complex chemical composition and has made a great contribution in the past decades [30]. With the development of more advanced analytical methods like mass spectrometric, gas chromatography and so on, more characteristic substances can be detected, and the quality control of the herbal injections has been greatly improved. However, the chemical composition of herbal injections is very complex and it is rather difficult to identify all the components using the present analytical methods. Meanwhile, even if all the components could be identified, the relevance between the components and the clinical efficacy or adverse reactions of the herbal injections would still remain unexplained. Many laboratory studies have demonstrated that QC relying mainly on CF is insufficient for herbal products since it cannot reflect the clinical efficacy and any unknown materials may pose a risk to patients [18, 31].

In this study, together with the establishment of CF, we first implemented the real-time, cell-based methodology for the detection of quality fluctuation of an herbal injection. As shown in Fig. 3, the chemical fingerprint of the samples stored at high-temperature or under extreme illumination changed obviously compared with the normal samples. Research about the chemical stability testing of herbal extracts showed that raising the temperature could accelerate the kinetics of the redox reactions [32]. Five peaks (a, b, c, d, e) in the normal samples could hardly be detected after treatment with high-temperature, potentially due to their characteristic of thermal instability. Besides, there might exist some other undetected thermal instability compositions which contribute to the increasing of area of peak g and the appearance of a new peak at the retention time of 78.7 min. Light is another important factor, which affects the stability of a variety of plant metabolites, such as flavonoids. Areas of peak 6 and 10 (isochlorogenic acid B and baicalein) increased in samples treated with extreme illumination, a new peak appeared at the retention time of 60.9 min, indicating that some compositions of SHL were optical instability. Finally, these compositional changes upon stress conditions might immediately lead to the variation of bioactivity and quality of the samples. Thus, using similarity and multivariate statistical analysis, both the CF and BF method could accurately discriminate the high-temperature and extreme illumination accelerated SHL samples from normal samples.

When exposed to the environment, the drug molecules or active components of the samples are subjecting to oxidation, hydrolysis, microbial attack and other environmental degradation which poses a problem of stability to the products [32, 33]. The main constituents of SHL are as follows: organic acids, flavonoids, triterpenoids, lignans, saccharides, volatile oils, etc. Among which the organic acids, phenolic acids flavonoids and iridoids are vulnerable to air oxidation and hydrolysis, the physical and chemical stability and bioactivity of the samples may vary with time under the influence of the environmental factors, leading to the creation of degradation products, although no compositional changes were detected under the given chromatographic conditions (Fig. 3). In addition, when exposed to the environment, airborne bacteria may enter the sterilization containers and lead to contamination. Bacterial contamination has been reported to be one of the major reasons for adverse events of some herbal injections [34]. Many studies have shown that the existence of bacterial and lipopolysaccharide can lead to the activation of mast cells and release of various anaphylactic mediators [35–37]. Meanwhile, along with this process, the morphology and membranes of the mast cells begin to change. The cells may detach from the culture plate gradually and result in a decline in the CI values recorded by the impedance-based xCELLigence system. This may be the reason why the biological activity of samples from the group of ES was much stronger than that of NS (Fig. 6). Therefore, the BF method could clearly discriminate ES from NS.

In the present study, the TCRP-based technique was used to establish the biological fingerprint for the QC of an herbal injection. The system is an impedance-based, label-free biosensor technology, which has a demonstrated applicability to provide continuous monitoring of cellular status including cell number, morphology, and cellular adherence in real time [38, 39]. Meanwhile, according to the different model cell selected, this TCRP technique can be helpful for various biological activity-based quality fluctuation detection.

Conclusion

The objective of this study was to establish a comprehensive approach for the QC of herbal injections by the quality fluctuation detection of normal and abnormal samples of SHL via chemical and biological aspects. Multiple analysis methods were applied to evaluate the discriminant ability of the chemical and biological fingerprints. CF, the most important and most commonly used method for the QC of herbal injections, could accurately distinguish abnormal samples with noticeable changes in chemical constituents. However, samples subjecting to environmental influence like oxygen/air could not be discriminated by CF. For the BF method, all samples could be clearly discriminated since both the potential biological pollution and changes in chemical constituents may lead to variations in biological activity. In summary, BF provided a more powerful and meaningful tool for the detection of quality fluctuation of SHL and could provide reference for the QC of other herbal injections. It is our belief that this new method, together with other emerging advances in biological technologies, may open a promising new avenue for the QC of herbal medicines.

References

Normile D (2003) The new face of traditional Chinese medicine. Science 299:188–190

Cho WCS (2010) Supportive cancer care with Chinese medicine. Springer, Netherlands

Wheeler RH, Busby L, Samlowski W, Gerard R, Farling H (2003) Phase I study of kanglaite (KLT) a botanical product based on traditional Chinese medicine. American Society of Clinical Oncology (ASCO) Annual Meeting, Chicago, IL.

Huang H, Qu H (2011) In-line monitoring of alcohol precipitation by near-infrared spectroscopy in conjunction with multivariate batch modeling. Anal Chim Acta 707:47–56

Ma YC, Wang XQ, Hou FF, Ma J, Luo M, Chen A, Jin P, Lu A, Xu I (2011) Rapid resolution liquid chromatography (RRLC) analysis and studies on the stability of Shuang-Huang-Lian preparations. J Pharm Biomed Anal 54:265–272

Chen W, Lim CED, Kang HJ, Liu J (2011) Chinese herbal medicines for the treatment of type A H1N1 influenza: a systematic review of randomized controlled trials. PLoS ONE 6:e28093

Zeng ZP, Jiang JG (2010) Analysis of the adverse reactions induced by natural product-derived drugs. Br J Pharmacol 159:1374–1391

Huang H, Qu H (2013) A comparative fingerprint study using high-performance liquid chromatography, ultraviolet, and near-infrared spectroscopy to evaluate the quality consistency of Danshen injections produced by different manufacturers. Anal Methods 5:474–482

Wang XF, Liu JP, Shen KL, Ma R, Cui ZZ, Deng L, Shang YX, Zhao DY, Wang LB, Wan LY, Sun YQ, Li YN, Jiang ZY, Xu H, Li XM, Wu ZQ, Liu ZL, Hu YH, Huang Y, He CH, Zhang H, Jiang YH, Liu H, Wang Z (2013) A cross-sectional study of the clinical characteristics of hospitalized children with community-acquired pneumonia in eight eastern cities in China. BMC Complement Altern Med 13:367

Ji K, Chen J, Li M, Liu Z, Xia L, Wang C, Zhan Z, Wu X (2009) Comments on serious anaphylaxis caused by nine Chinese herbal injections used to treat common colds and upper respiratory tract infections. Regul Toxicol Pharmacol 55:134–138

Qiu J (2007) Traditional medicine: a culture in the balance. Nature 448:126–128

Wu L, Gong P, Wu Y, Liao K, Shen H, Qi Q, Liu H, Wang G, Hao H (2013) An integral strategy toward the rapid identification of analogous nontarget compounds from complex mixtures. J Chromatogr A 1303:39–47

Zhai HL, Li BQ, Tian YL, Li PZ, Zhang XY (2014) An application of wavelet moments to the similarity analysis of three-dimensional fingerprint spectra obtained by high-performance liquid chromatography coupled with diode array detector. Food Chem 145:625–631

Yan S, Xin W, Luo G, Wang Y, Cheng Y (2005) An approach to develop two-dimensional fingerprint for the quality control of Qingkailing injection by high-performance liquid chromatography with diode array detection. J Chromatogr A 1090:90–97

Zeng S, Chen T, Wang L, Qu H (2013) Monitoring batch-to-batch reproducibility using direct analysis in real time mass spectrometry and multivariate analysis: A case study on precipitation. J Pharm Biomed Anal 76:87–95

Coghlan ML, Haile J, Houston J, Murray DC, White NE, Moolhuijzen P, Bellgard MI, Bunce M (2012) Deep sequencing of plant and animal DNA contained within traditional Chinese medicines reveals legality issues and health safety concerns. PLoS Genet 8:e1002657

Huang MD, Becker-Ross H, Florek S, Okruss M, Welz B, Morés S (2009) Determination of iodine via the spectrum of barium mono-iodide using high-resolution continuum source molecular absorption spectrometry in a graphite furnace. Spectrochim Acta Part B At Spectrosc 64:697–701

Jiang Y, David B, Tu P, Barbin Y (2010) Recent analytical approaches in quality control of traditional Chinese medicines—a review. Anal Chim Acta 657:9–18

Fu H, Fu W, Sun M, Shou Q, Zhai Y, Cheng H, Teng L, Mou X, Li Y, Wan S, Zhang S, Xu Q, Zhang X, Wang J, Zhu J, Wang X, Xu X, Lv G, Jin L, Guo W, Ke Y (2011) Kinetic cellular phenotypic profiling: prediction, identification, and analysis of bioactive natural products. Anal Chem 83:6518–6526

Ren Y, Zhang P, Yan D, Wang J, Du X, Xiao X (2011) A strategy for the detection of quality fluctuation of a Chinese herbal injection based on chemical fingerprinting combined with biological fingerprinting. J Pharm Biomed Anal 56:436–442

Abassi YA, Xi B, Zhang W, Ye P, Kirstein SL, Gaylord MR, Feinstein SC, Wang X, Xu X (2009) Kinetic cell-based morphological screening: prediction of mechanism of compound action and off-target effects. Chem Biol 16:712–723

Ke N, Xi B, Ye P, Xu W, Zheng M, Mao L, Wu MJ, Zhu J, Wu J, Zhang W, Zhang J, Irelan J, Wang X, Xu X, Abassi YA (2010) Screening and identification of small molecule compounds perturbing mitosis using time-dependent cellular response profiles. Anal Chem 82:6495–6503

Xia M, Huang R, Witt KL, Southall N, Fostel J, Cho MH, Jadhav A, Smith CS, Inglese J, Portier CJ, Tice RR, Austin CP (2008) Compound cytotoxicity profiling using quantitative high-throughput screening. Environ Health Perspect 116:284

Passante E, Frankish N (2009) The RBL-2H3 cell line: its provenance and suitability as a model for the mast cell. Inflamm Res 58:737–745

Liu X, Luan Y, Guo A, Deng H, Lu Z (2012) Dynamic investigation of sensitivity and action mechanism of antitumor drug. Adv Mat Res 343:476–482

Pan T, Huang B, Zhang W, Gabos S, Huang DY, Devendran V (2013) Cytotoxicity assessment based on the AUC50 using multi-concentration time-dependent cellular response curves. Anal Chim Acta 764:44–52

Kustermann S, Boess F, Buness A, Schmitz M, Watzele M, Weiser T, Singer T, Suter L, Roth A (2013) A label-free, impedance-based real time assay to identify drug-induced toxicities and differentiate cytostatic from cytotoxic effects. Toxicol In Vitro 27:1589–1595

Yang DZ, An YQ, Jiang XL, Tang DQ, Gao YY, Zhao HT, Wu XW (2011) Development of a novel method combining HPLC fingerprint and multi-ingredients quantitative analysis for quality evaluation of traditional Chinese medicine preparation. Talanta 85:885–890

Han C, Shen Y, Chen J, Lee FSC, Wang X (2008) HPLC fingerprinting and LC–TOF-MS analysis of the extract of Pseudostellaria heterophylla (Miq.) Pax root. J Chromatogr B 862:125–131

Liang YZ, Xie P, Chan K (2004) Quality control of herbal medicines. J Chromatogr B 812:53–70

Ren Y, Zhang P, Yan D, Yan Y, Chen L, Qiu L, Mei Z, Xiao X (2012) Application of microcalorimetry of Escherichia coli growth and discriminant analysis to the quality assessment of a Chinese herbal injection (Yinzhihuang). Acta Pharm Sin B 2:278–285

Gafner S, Bergeron C (2005) The challenges of chemical stability testing of herbal extracts in finished products using state-of-the-art analytical methodologies. Curr Pharm Anal 1:203–215

Thakur L, Ghodasra U, Patel N, Dabhi M (2011) Novel approaches for stability improvement in natural medicines. Pharmacogn Rev 5:48–54

Du W, Guo JJ, Jing Y, Li X, Kelton CML (2008) Drug safety surveillance in China and other countries: a review and comparison. Value Health 11:S130–S136

Muñoz S, Hernández-Pando R, Abraham SN, Enciso JA (2003) Mast cell activation by Mycobacterium tuberculosis: mediator release and role of CD48. J Immunol 170:5590–5596

Marshall JS (2004) Mast-cell responses to pathogens. Nat Rev Immunol 4:787–799

Rocha-de-Souza CM, Berent-Maoz B, Mankuta D, Moses AE, Levi-Schaffer F (2008) Human mast cell activation by Staphylococcus aureus: interleukin-8 and tumor necrosis factor alpha release and the role of Toll-like receptor 2 and CD48 molecules. Infect Immun 76:4489–4497

Mou X, Wan S, Li Y, Zhang S, Sun M, Liu F, Fu H, Zhang X, Liu H, Cao Q, Ke Y, Xiang C (2011) Phenotypic pattern-based assay for dynamically monitoring host cellular responses to Salmonella infections. PLoS ONE 6:e26544

Boyd JM, Huang L, Xie L, Moe B, Gabos S, Li XF (2008) A cell-microelectronic sensing technique for profiling cytotoxicity of chemicals. Anal Chim Acta 615:80–87

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant No. 81274078, 81322052, 81303222) and China Postdoctoral Science Foundation (Grant No. 2013 M532130).

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

ESM 1

(PDF 109 kb)

Rights and permissions

About this article

Cite this article

Zhang, L., Ma, L., Feng, W. et al. Quality fluctuation detection of an herbal injection based on biological fingerprint combined with chemical fingerprint. Anal Bioanal Chem 406, 5009–5018 (2014). https://doi.org/10.1007/s00216-014-7918-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00216-014-7918-1