Abstract

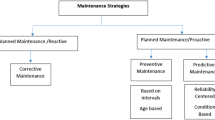

Numerous of maintenance policies were developed due to the change in the manufacturing environment and the growing of technologies in the past few decades. Due to fluctuation (oscillation, instability) phenomena of the manufacturing industry, it is difficult to identify an optimal maintenance policy that actually suit for a manufacturing system. Thus, a lot of efforts have been done in order to assist manufacturing industry in finding an optimal maintenance policy. This paper attempts to review past and current research on optimal maintenance policy selection issues associated with methods used as well as the applications. Published literatures were systematically classified based on certainty theory in operation management classification model in term of certainty, uncertainty, and risk. Furthermore, a sub family had been classified based on the approaches used in determining the optimal maintenance policy. The possible gap occurred between academic research and industrial application in maintenance policy optimization is also discussed in detail, and several possible ideas are put forward to reduce the gap. More importantly, the paper is intended to provide a different view on classifying these models and give useful references for personnel working in industrial as well as researchers.

Similar content being viewed by others

References

Swanson L (2001) Linking maintenance strategies to performance. Int J Prod Econ 709(3):237–244

Madu CN (2000) Competing through maintenance strategies. Int J Quality Reliab 17(9):937–948

Mobley RK (2002) An introduction to predictive maintenance. Buttherworth-Heinemann, Woburn

Tan MT, Raghavan N (2007) Root cause analysis based maintenance policy. Int J Quality Reliab Manag 24(2):203–228

Lu KY, Sy CC (2009) A real-time decision-making of maintenance using fuzzy agent. Expert Syst Appl 36(2):2691–2698

Gupta S, Maiti J, Kumar R, Kumar U (2009) A control chart guided maintenance policy selection. Int J Min Reclam Environ 23(3):216–226

Xia T, Xi L, Lee J, Zhou X (2011) Optimal CBPM policy considering maintenance effects and environmental condition. Int J Adv Manuf Technol 56:1181–1193

Sharma A, Yadava GS, Deshmukh SG (2011) A literature review and future perspectives on maintenance optimization. J Qual Maint Eng 17(1):5–25

Wang W (2012) A stochastic model for joint spare parts inventory and planned maintenance optimization. Eur J Oper Res 216(1):127–139

Bevilacqua B, Braglia M (2000) The analytic process applied to maintenance strategy selection. Reliab Eng Syst Safe 70(1):71–83

Khazraei K, Deuse J (2011) A strategic standpoint on maintenance taxonomy. J Facil Manag 9(2):96–113

Mechefske CK, Wang Z (2001) Using fuzzy linguistics to select optimum maintenance and condition monitoring strategies. Mech Syst Signal Process 15(6):1129–1140

Sharma RK, Kumar D, Kumar P (2005) FLM to select suitable maintenance strategy in process industries using MISO model. J Qual Maint Eng 1(11):359–374

Peng Y, Dong M, Zuo MJ (2010) Current status of machine prognostics in condition-based maintenance—a review. Int J Adv Manuf Technol 34:1181–1193

Wang L, Chu J, Wu J (2007) Selection of optimum maintenance strategies based on a fuzzy analytical hierarchy process. Int J Prod Econ 107(1):151–163

Arunraj NS, Maiti J (2010) Risk-based maintenance policy selection using AHP and goal programming. Saf Sci 48(2):238–247

Mechefske CK, Wang Z (2001) Using fuzzy linguistics to select optimum maintenance and condition monitoring strategies. Mech Syst Signal Process 15(6):1129–1140

Alsyouf I (2007) The role of maintenance in improving companies’ productivity and profitability. Int J Prod Econ 105(1):70–78

Tajiri M, Gotoh F (1992) TPM implementation—a Japanese approach. McGraw Hill Inc, New York

Schuh G, Lorenz B, Winter CP, Gudergan G (2010) The house of maintenance-identifying the potential for improvement in internal maintenance organization by means of a capability maturity model. Springer, London

Zaied RA, Abhary K, Gomaa AH (2010) Intelligent integrated maintenance of manufacturing systems. In: Engineering the future, book chapter 15. DOI: 10.5772/10379

Park K, Moon S (2005) Optimal design of heat exchangers using the progressive quadratic response surface model. Int J Heat Mass Transf 48(11):2126–2139

Munoz A, Martorell S, Serradell V (1997) Genetic algorithms in optimizing surveillance and maintenance of components. Reliab Eng Syst Safe 57(2):107–120

Chen G, Trung TP (2006) Introduction to fuzzy system. Chapman & Hall/CRC, Florida

Geradas WMJ (1992) The EUT maintenance model. Int J Prod Econ 24(3):209–216

Marais KB, Saleh JH (2009) Beyond its cost, the value of maintenance: an analytical framework for capturing its net present value. Reliab Eng Syst Safe 94(2):644–657

Tersine RJ (1985) Production/operations management: concepts, structure, and analysis. Elsevier Science Publisher, New York

Labib AW. (1998) World-class maintenance using a computerised maintenance management system. Journal of Quality in Maintenance Engineering 4 (1):66–75

Fernandez O, Labib AW, Walmsley R, Petty DJ (2003) A decision support maintenance management system. Int J Qual Reliab Manag 20(8):965–979

Labib AW (2004) A decision analysis model for maintenance policy selection using a CMMS. J Qual Maint Eng 10(3):191–202

Khalil J, Saad SM, Gindy N, MacKechnie K (2005) A maintenance policy selection tool for industrial machine parts. Int Fed Inform Process Emerg Sol Future Manufac 159:431–440

Burhanuddin MA, Ahmad AR, Desa MI (2007) An application of decision making grid to improve maintenance strategies in small and medium industries. IEEE International Industrial Electronics and Application Conference Proceedings, Harbin, pp 455–460

Tahir Z, Burhanuddin MA, Ahmad AR, Halawani SM, Arif F (2009) Improvement of decision making grid model for maintenance management in small and medium industries. Industrial and Information Systems International Conference Proceeding, Sri Lanka, pp 598–603

Labib AW, Yunitaro MN (2009) Maintenance strategies for changeable manufacturing. In changeable and reconfigurable manufacturing systems. Springer: Verlag, London. Book chapter

Almeida AT, Bohoris GA (1995) Decision theory in maintenance decision making. J Qual Maint Eng 1(1):39–45

Lugtigheid D, Banjevic D, Jardine AKS (2004) Modelling repairable system reliability with explanatory variables and repair and maintenance actions. J Manag Math 15:89–110

Samrout M, Chatelet E, Kouta R, Chebbo N (2009) Optimization of maintenance policy using the proportional hazard model. Reliab Eng Syst Safe 94(1):44–52

Martorell S, Sanchez A, Serradell V (1999) Age-dependent reliability model considering effects of maintenance and working conditions. Reliab Eng Syst Safe 64(1):19–31

El-Gogary A. (2004) Estimations of parameters in a three state reliability semi-Markov model. Applied Mathematics and Computation 154:389–403

Gurler U, Kaya AA (2002) Maintenance policy for a system with multi-state components: an approximate solution. Reliab Eng Syst Safe 76(2):117–127

Amari SV, McLaughlin L, Pham H (2006) Cost-effective condition-based maintenance using Markov decision processes. Reliability and Maintainability Symposium, Newport Beach, pp 464–469

Nourelfath M, Ait-Kadi D (2007) Optimization of series–parallel multi-state systems under maintenance policies. Reliab Eng Syst Safe 92(12):1620–1626

Anders GJ, Sugier J (2006) Risk assessment tool for maintenance selection. Dependability of Computer Systems International Conference Proceedings, Szklarska Poreba, pp 306–313

Ge H, Tomasevicz CL, Asgaspoor S (2007) Optimum maintenance policy with inspection by semi-Markov decision processes. Power American Symposium, Las Cruces, pp 17–19

Kenne JP, Nkeungoue LJ (2008) Simultaneous control of production, preventive and corrective maintenance rates of a failure-prone manufacturing system. Appl Numer Math 58:180–194

Muller A, Suhner MC, Iung B (2008) Formalisation of a new prognosis model for supporting proactive maintenance implementation on industrial system. Reliab Eng Syst Safe 93(2):234–253

Marais KB, Saleh JH (2009) Beyond its cost, the value of maintenance: an analytical framework for capturing its net present value. Reliab Eng Syst Safe 94(2):744–657

Ponchet A, Fouladirar M, Grall A (2010) Assessment of a maintenance model for a multi-deteriorating mode system. Reliab Eng Syst Safe 95(11):1244–1254

Chelbi A, Ait-Kadi D (1999) An optimal inspection strategy for randomly failing equipment. Reliab Eng Syst Safe 63(2):127–131

Lofsten H (1999) Management of industrial maintenance-economic evaluation of maintenance policies. Int J Opera Prod Manag 19(7):716–737

Cassady CR, Pohl EA, Murduck WP (2001) Selective maintenance modeling for industrial systems. J Qual Maint Eng 7(2):104–117

Goel HD, Grievink J, Weijnen MPC (2003) Integrated optimal reliable design, production and maintenance planning for multipurpose process plants. Comput Chem Eng 27(11):1543–1555

Marquez AC, Gupta JND, Heguedas AS (2003) Maintenance policies for a production system with constrained production rate and buffer capacity. Int J Prod Res 41(9):1909–1926

Pongpech J, Murthy DNP, Boondiskulchock R (2006) Maintenance strategies for used equipment under lease. J Qual Maint Eng 12(1):52–67

Nielsen JJ, Sorensen JD (2011) On risk-based operation and maintenance of offshore wind turbine components. Reliab Eng Syst Safe 96(1):218–229

Young MJ (2003) Human performance model validation: one size does not fit all. Summer Computer Simulation Conference, 732–735

Bogonovo E, Marseguerra M, Zio E (2000) A Monte Carlo methodological approach to plant availability modelling with maintenance, aging and obsolescence. Reliab Eng Syst Safe 67(1):61–73

Vant J (1997) Maintenance optimisation from a decision theoretical point of view. Reliab Eng Syst Saf 58:119–126

Chen T, Popova E (2002) Maintenance policies with two dimensional warranty. Reliab Eng Syst Saf 77(1):61–69

Barata CJ, Guedes S, Marseguerra M, Zio E (2002) Simulation modelling of repairable multi-component deteriorating systems for on condition maintenance optimisation. Reliab Eng Syst Saf 76(3):255–264

Silva AML, Manso LAF, Anders GJ (2004) Evaluation of generation and transmission maintenance strategies based on reliability worth. Electr Power Syst Res 71:99–107

Hilber P, Miranda V, Matos MA, Bertling L (2007) Multiobjective optimization applied to maintenance policy for electrical networks. IEEE Trans Pow Syst 22(4):1675–1682

Nguyen DQT, Miguel J, Bagajewicz J (2009) On the impact of sensor maintenance policies on stochastic-based accuracy. Comput Chem Eng 33(9):1491–1498

Clavareau J, Laeau PE (2009) Maintenance and replacement policies under technological obsolescence. Reliab Eng Syst Saf 94(2):370–381

Mercier S, Laneau PE (2004) Optimal replacement policy for a series system with obsolescence. Appl Stochastic Model Bus Indust 20:73–91

Huynh KT, Barros A, Berenguer C (2012) Maintenance decision-making for systems operating under indirect condition monitoring: value of online information and impact of measurement uncertainty. IEEE Trans Reliab 61(2):410–425

Hu J, Zhang L (2014) Risk based opportunistic maintenance model for complex mechanism systems. Expert Syst Appl 41(6):3105–3115

Houten FJAMV, Tomiyama T, Salomons OW (2009) Product modeling for model-based maintenance. Annals of the CIRP 47(1):123–128

Li Z, Liao H (2007) Simulation-based decision making for maintenance policy selection for complex systems. Automation and Logistic International Conference, Jinan, pp 29–30

Boschian V, Rezg N, Chelbi A (2009) Contribution of simulation to the optimization of maintenance strategies for a randomly failing production system. Eur J Oper Res 197:1142–1149

Kaegi M, Mock R, Kroger W (2009) Analyzing maintenance strategies by agent-based simulations: a feasibility study. Reliab Eng Syst Saf 94(9):1416–1421

Sarker R, Haque A (2000) Optimization of maintenance and spare provisioning policy using simulation. Appl Math Model 24:751–760

Kabir Z, Olayan SA (1996) Joint optimization of age based preventive replacement and continuous review spare provisioning policy. Eur J Oper Res 90:171–181

Mattila V, Virtanen K, Raivio T (2003) A simulation model for aircraft maintenance in an uncertain operational environment. European Simulation Multiconference Proceedings, Nottingham, pp 456–461

Takata S, Kimura F, Houten FJAM. Westkamper E. Maintenance: changing role in life cycle management. CIRP Annals-Manufacturing Technology 53 (2):643–655

Krishnasamy L, Khan F, Haddara M (2005) Development of a risk-based maintenance (RBM) strategy for a power-generating plant. J Loss Prev Process Ind 18:69–81

Dingzhou C, Sun Y, Guo H. (2013) Optimizing maintenance policies based on discrete event simulation and the OCBA mechanism. In: Proceedings of Reliability and Maintainability Symposium, 28–31 Jan 2013, Orlando, Florida, p. 1–6

Marseguerra M, Zio E (2000) Optimizing maintenance and repair policies via a combination of genetic algorithms and Monte Carlo simulation. Reliab Eng Syst Saf 68(1):69–83

Vineyard M, Amoako-Gyampah K, Meredith JR (2000) An evaluation of maintenance policies for flexible manufacturing systems. Int J Opera Prod Manag 20(4):409–426

Savsar M (2005) Performance analysis of an FMS operating under different failure rates and maintenance policies. Int J Flex Manuf Syst 16:229–249

Savsar M (2006) Effects of maintenance policies on the productivity of flexible manufacturing cells. Int J Manag Sci 34:274–282

Malamura E, Murata T (2012) Simulation based plant maintenance planning with multiple maintenance policy and evaluation of production process dependability. In: Proceedings of the International Multi Conference of Engineers and Computer Scientists. 14–16 March 2012. Hong Kong

Azadeh A, Sheikhalishahi M, Firoozi M, Khalili SM (2013) An integrated multi-criteria Taguchi computer simulation-DEA approach for optimum maintenance policy and planning by incorporating learning effects. Int J Prod Res 51(18):5374–5385

Azadeh A, Sheikhalishahi M, Khalili SM, Firoozi M (2014) An integrated fuzzy simulation-fuzzy data envelopment analysis approach for optimum maintenance planning. Int J Comput Integr Manuf 27(2):181–199

Domshlak C, Hullermeier E, Kaci S, Prade H (2011) Preferences in AI—an overview. Artif Intell 175(7–8):1037–1052

Kobaccy KAH (2008) Artificial intelligence in maintenance. Springer Verlag, London

Mitchell M (1998) An introduction to genetic algorithm. MIT Press, United States of America

Martorell S, Villanueva JF, Carlos S, Nebot Y, Sanchez A, Pitarch JL, Serradell V (2005) RAMS + C informed decision-making with application to multi-objective optimization of technical specifications and maintenance using genetic algorithms. Reliab Eng Syst Saf 87(1):65–75

Morcous G, Lounis Z (2005) Maintenance optimization on infrastructure networks using genetic algorithms. Autom Constr 14(1):129–142

Ilgin MA, Tunali S (2007) Joint optimization of spare parts inventory and maintenance policies using genetic algorithms. Int J Adv Manuf Technol 34:594–604

Okasha NM, Frangopol DM (2009) Lifetime-oriented multi-objective optimization of structural maintenance considering system reliability, redundancy and life-cycle cost using GA. Struct Saf 31(6):460–474

Chung SH, Lau HCW, Ho GTS, Ip WH (2009) Optimization of system reliability in multi-factory production networks by maintenance approach. Expert Syst Appl 36(6):10188–10196

Heo JH, Park GP, Yoon YT, Park JK, Lee SS (2010) Optimal maintenance strategies for transmission systems using the genetic algorithm. Transmission and Distribution Conference Proceedings, New Orleans, pp 1–6

Martorell S, Villamizar M, Carlos S, Sanchez A (2010) Maintenance modeling and optimization integrating human and material resources. Reliab Eng Syst Saf 95(12):1293–1299

Charongrattanasakul P, Pongpullponsak A (2011) Minimizing the cost of integrated systems approach to process control and maintenance model by EWMA control chart using genetic algorithm. Expert Syst Appl 38:5178–5186

Marseguerra M, Zio E (2000) Optimizing maintenance and repair policies via a combination of genetic algorithms and Monte Carlo simulation. Reliab Eng Syst Saf 68(1):69–83

Villanueva JF, Sanchex AI, Carlos S, Martorell S (2008) Genetic algorithm-based optimization of testing and maintenance under uncertain unavailability and cost estimation: a survey of strategies for harmonizing evolution and accuracy. Reliab Eng Syst Saf 93(12):1830–1841

Mahadevan ML, Paul Robert T, Sridhar V (2010) Optimizing maintenance activities using HGA and Monte Carlo simulation. Int J Comput Appl 1(21):106–110

Waeyenbergh G, Pintelon L (2002) A framework for maintenance concept development. Int J Prod Econ 77(3):299–313

Waeyenbergh G, Pintelon L (2004) Maintenance concept development: a case study. Int J Prod Econ 89(3):398–405

Waeyenbergh G, Pintelon L (2009) CIBOCOF: a framework for industrial maintenance concept development. Int J Prod Econ 121(2):633–640

Carazsa FG, Souza GFM (2000) Risk-based decision making method for maintenance policy selection of thermal power plant equipment. Energy 35:964–975

Ding SH, Goh TT, Tan PS, Wee SC, Kamaruddin S (2012) Implementation of decision tree for maintenance policy decision making—a case study in semiconductor industry. Adv Mater Res 591–593:704–707

Bevilacqua M, Braglia M, Gabbrielli R (2000) Monte Carlo simulation approach for a modified FMECA in a power plant. Qual Reliab Eng Int 16:313–324

Tu PYL, Yam R, Tse P, Sun AOW (2001) An integrated maintenance management system for an advanced manufacturing company. Int J Adv Manuf Technol 17:692–703

Leon Hijes FCG, Cartagena JJR (2006) Maintenance strategy based on a multicriterion classification of equipments. Reliab Eng Syst Saf 91(4):444–451

Rosqvist T, Laakso K, Reunnanen M (2009) Value-driven maintenance planning for a production plant. Reliab Eng Syst Saf 94(1):97–110

Qingfeng W, Wenbin L, Xin Z, Jianfeng Y, Qingbin Y (2011) Development and application of equipment maintenance and safety integrity management system. J Loss Prev Process Ind 24(4):321–332

Li D, Gao J (2010) Study and application of reliability-centered maintenance considering radical maintenance. J Loss Prev Process Ind 23(5):622–629

Popovic VM, Vasic BM, Rakicevic BB, Vorotovic GS (2011) Optimisation of maintenance concept choice using risk factor-decision factor-a case study. International Journal of System Sciences 1–14

Lv C, Xiong J, Ding Y, Zhou H (2013) A maintenance decision-making model based on risk evaluation. In: Proceedings of International Conference on Quality, Reliability, Risk, Maintenance and Safety Engineering. 15–18 July 2013, Chengdu, China, p. 684–688

Braglia M, Frosolini M, Montanari R (2003) Fuzzy criticality assessment model for failure modes and effects analysis. Int J Qual Reliab Manag 20(4):503–524

Dong YL, Gu YJ, Dong XF (2008) Selection of optimum maintenance strategy for power plant equipment based on evidential reasoning and FMEA. IEEE International Industrial Engineering and Engineering Management Conference Proceedings, Singapore, pp 862–866

Guo L, Gao J, Yang J, Kang J (2009) Criticality evaluation of petrochemical equipment based on fuzzy comprehensive evaluation and a BP neural network. J Loss Prev Process Ind 22(4):469–476

Azedah A, Ebrahimipour V, Bavar P (2010) A fuzzy inference system for pump failure diagnosis to improve maintenance process: the case of a petrochemical industry. Experts Syst Appl 37(1):627–639

Sharma RK, Sharma P (2010) System failure behavior and maintenance decision making using RCA, FMEA and FM. J Qual Maint Eng 16(1):64–88

Braglia M, Frosolini M, Montanari R (2003) Fuzzy criticality assessment model for failure modes and effects analysis. Int J Qual Reliab Manag 20(4):503–524

Vinodh S, Varadharajan AR (2012) Application of fuzzy VIKOR for concept selection in agile environment. Int J Adv Manuf Technol 42:1025–1033

Karaarslan N, Gundogar E (2009) An application for modular capability-based ERP software selection using AHP method. Int J Adv Manuf Technol 42:1025–1033

Pohekar SD, Ramachandran M (2004) Application of multi-criteria decision making to sustainable energy planning—a review. Renew Sust Energ Rev 8(4):365–381

Dey PK (2004) Decision support system for inspection and maintenance: a case study of oil pipelines. IEEE Trans Eng Manag 51(1):47–56

Fazlollahtabar H, Yousefpoor N (2008) Selection of optimum maintenance strategies in a virtual learning environment based on analytic hierarchy process. Virtual Learning International Conference Proceeding, Constanţa, pp 143–152

Gassner S (2010) Deriving maintenance strategies for cooperative alliances-a value chain approach. Managing Operations in Service Economies International Conference Proceeding, Porto

Ratnayake RMC, Markeset T (2010) Technical integrity management: measuring HSE awareness using AHP in selecting a maintenance strategy. J Qual Maint Eng 16(1):44–63

Tan Z, Li J, Wu Z, Zheng J, He W (2011) An evaluation of maintenance strategy using risk based inspection. Saf Sci 49(6):852–860

Shyjith K, Ilangkumaran M, Kumanan S (2008) Multi-criteria decision-making approach to evaluate optimum maintenance strategy in textile industry. J Qual Maint Eng 14(4):375–386

Ding SH, Kamaruddin S, Azid IA (2014) Development of a model for optimal maintenance policy selection. Eur J Indust Eng 8(1):50–68

Ding SH, Kamaruddin S, Azid IA (2014) Maintenance policy selection model—a case study in the palm oil industry. J Manuf Technol Manag 25(3):415–435

Cheng YH, Tsao HL (2010) Rolling stock maintenance strategy selection, spares parts’ estimation and replacement interval calculation. Int J Prod Econ 128(1):404–412

Zaim S, Turkyilmaz A, Acar MF, Al-Turki U, Demirel OF (2012) Maintenance strategy selection using AHP and ANP algorithms: a case study. J Qual Maint Eng 18(1):16–29

Aghaie M, Fazli S (2012) An improved MCDM method for maintenance approach selection: a case study of auto industry. Manag Sci Lett 2(1):137–146

Kumar G, Maiti J (2012) Modeling risk based maintenance using fuzzy analytic network process. Experts Syst Appl 39(11):9946–9954

Rahimi M, Sadinejad S, Khalili-Damghani K (2014) Selecting the most appropriate maintenance strategies using fuzzy analytic network process: a case study of Saipa vehicle industry. Dec Sci Lett 3(2):237–242

Labib AW (2004) A decision analysis model for maintenance policy selection using a CMMS. J Qual Maint Eng 10(3):191–202

Bertolini M, Bevilacqua M (2006) A combined goal programming-AHP approach to maintenance selection problem. Reliab Eng Syst Saf 91(7):839–848

Ghosh D, Roy S (2010) A decision-making framework for process plant maintenance. Euro J Indust Eng 4(1):78–98

Pariazar M, Shahrabi J, Zaeri MS, Parhizi S (2008) A combined approach for maintenance strategy selection. J Appl Sci 8(23):4321–4329

Ilangkumaran M, Kumanan S (2009) Selection of maintenance policy for textile industry using hybrid multi-criteria decision making approach. J Manuf Technol Manag 20(7):1009–1022

Ahmadi A, Gupta S, Karim R, Kumar U (2010) Selection of maintenance strategy for aircraft systems using multi-criteria decision making methodologies. Int J Reliab Qual Saf Eng 17(3):223–243

Chen FL, Chen YC (2010) Evaluating the maintenance performance of the semiconductor factories based on the analytical hierarchy process and grey relational analysis. Am J Appl Sci 7(4):567–574

Fouladgar MM, Yazdani-Chamzini A, Lashgari A, Zavadskas EK, Turkis Z (2012) Maintenance strategy selection using AHP and COPRAS under fuzzy environment. Int J Strateg Prop Manag 16(1):85–104

Chan FTS, Prakash A (2012) Maintenance policy selection in manufacturing firms using the fuzzy MCDM approach. Int J Prod Res 50(23):7044–7056

Al-Najjar B, Alsyouf I (2003) Selecting the most efficient maintenance approach using fuzzy multiple criteria decision making. Int J Prod Econ 84(1):85–100

Jafari A, Jafarian M, Zareei A, Zaerpour F (2008) Using fuzzy Delphi method in maintenance strategy selection problem. J Uncert Syst 2(4):289–298

Li C, Xu M, Guo S (2007) ELECTRE III based on ranking fuzzy numbers for deterministic and fuzzy maintenance strategy decision problems. Automation and Logistic IEEE International Conference Proceedings, Jinan, pp 309–312

Mousavi SS, Nezami FG, Heydar M, Aryanejad MB (2009) A hybrid fuzzy group decision making and factor analysis for selecting maintenance strategy. Computers & Industrial Engineering International Conference Proceedings, Troyes, pp 1204–1209

Bashiri M, Badri H, Hejazi TH (2011) Selecting optimum maintenance strategy by fuzzy interactive linear assignment method. Appl Math Model 35(1):152–164

Kans M (2009) The advancement of maintenance information technology—a literature review. J Qual Maint Eng 15(1):5–16

Kumar R, Panesar SS, Markeset T (2009) Development of technical integrity management service. J Qual Maint Eng 15(3):271–284

Chung SH, Lau HCW, Ho GTS, Ip WH (2009) Optimization of system reliability in multi-factory production networks by maintenance approach. Expert Syst Appl 36(6):10188–10196

Utne IB (2010) Maintenance strategies for deep-sea offshore wind turbine. J Qual Maint Eng 16(4):367–381

Kenezevic J, Odoom ER (2001) Reliability modeling of repairable systems using Petri nets and fuzzy Lambda-Tau methodology. Reliab Eng Syst Saf 73(1):1–17

Sergaki A, Kalaitzakis K (2002) A fuzzy knowledge based method for maintenance planning in a power system. Reliab Eng Syst Saf 77(1):19–30

Louit DM, Pascual R, Jardine AKS (2009) A practical procedure for the selection of time-to-time models based on the assessment of trends in maintenance data. Reliab Eng Syst Saf 94(10):1618–1628

Spurgin AJ (2002) Impact of systematic data collection on training control room crews. Procedings of Human Factors and Power Plants, Scottsdale, pp 1–5

Loften H (1999) Management of industrial maintenance-economic evaluation of maintenance policies. Int J Opera Prod Manag 19(7):716–737

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, SH., Kamaruddin, S. Maintenance policy optimization—literature review and directions. Int J Adv Manuf Technol 76, 1263–1283 (2015). https://doi.org/10.1007/s00170-014-6341-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6341-2