Abstract

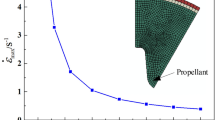

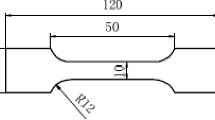

This research paper aims to develop a mathematical model for the interpretation of experimental data for propellant solids. A simple model is constructed by assuming a spherical unit cell. Equations are written with respect to the volume fraction of the filler particles as well as the fraction of the area that is unbonded. A sphere of a finite radius is assumed, containing a rubber matrix inside of which is a rigid filler particle of a smaller radius. A parameter is assigned for the porosity of the material while effective expressions for the shear and the bulk modulus and the strain energy function are written for the composite material. Based on the proposed strain energy function, the stress–strain relations are defined for the propellant solids. The model is based on four material parameters that were evaluated using Farris’s experimental data.

Similar content being viewed by others

References

Shen, L.-L., Shen, Z.-B., Xie, Y., Li, H.-Y.: effective mechanical property estimation of composite solid propellants based on VCFEM. Int. J. Aerospace Eng. 2018, 2050876 (2018)

Adel, W.M., Liang, G.-Z.: Analysis of mechanical properties for AP/HTPB solid propellant under different loading conditions. World Acad. Sci. Eng. Technol. Int. J. Aerospace Mech. Eng. 11(12), 1915–1919 (2017)

Kakavas, P.A.: Mechanical properties of propellant composite materials reinforced with ammonium perchlorate particles. Int. J. Solids Struct. 51(10), 2019–2026 (2014)

Fareghi, A.R., Moosavi Nadooshan, S.A., Zekri, N., Mohammadi-Vala, M.: Mechanical properties and burning rate studies of double-base propellants with Akarditeii, Centralite, or 2-Ndpa as stabilizers. J. Energ. Mater. 11(1), 55–60 (2016)

Rao, N.P., Solanke, C., Bihari, B.K., Singh, P.P., Bhattacharya, B.: evaluation of mechanical properties of solid propellants in rocket motors by indentation technique. Propellants Explos. Pyrotech. 41(2), 281–285 (2016)

Mason, B.P., Roland, C.M.: Solid propellants. Rubber Chem. Technol. 92(1), 1–24 (2019)

Eirich, F.R.Q.: Failure modes of elastomers. Eng. Fract. Mech. 5(3), 555–562 (1973)

Bueche, F.: Physical Properties of Polymers, p. 49. Wiley, New York (1962)

Farris, R.J.: The influence of vacuole formation on the response and failure of filled elastomers. J. Rheol. 12(2), 315–334 (1968)

Farris, R.J.: The character of the stress-strain function for highly filled elastomers. J. Rheol. 12(2), 303–314 (1968)

Farris, R.J., Falabella, R., Tsai, Y.D.: influence of vacuole formation and growth on the mechanical behavior of polymers. ACS Symp. Ser. 95, 233–243 (1978)

Dong, S., Herrmann, L., Pister, K., Taylor, R.: Studies relating to structural analysis of solid propellants. Final Report to Aerojet-General Corporation, Department of Civil Engineering, UCB (1962)

Ogden, R.W.: Large deformation isotropic elasticity - On the correlation of theory and experiment for incompressible rubberlike solids. Rubber Chem. Technol. 46(2), 398–416 (1973)

Lepie, A., Adicoff, A.: Dynamic mechanical behavior of highly filled polymers: Dewetting effect. J. Appl. Polym. Sci. 16(5), 1155–1166 (1972)

Mullins, L.: Effects of stretching on the properties of rubber. Rubber Chem. Technol. 21(2), 281–300 (1948)

Lion, A.: A constitutive model for carbon black filled rubber: experimental investigations and mathematical representation. Continuum Mech. Thermodyn. 8(3), 153–169 (1996)

Kakavas, P.A., Chang, W.V.: Acoustic emission in bonded elastomer discs subjected to uniform tension. J. Appl. Polym. Sci. 42(6), 1997–2004 (1991)

Kakavas, P.A.: New development of the strain energy function for hyperelastic materials using a logarithmic strain approach. J. Appl. Polym. Sci. 77(3), 660–672 (2000)

Kasner, A.I., Meinecke, E.A.: Porosity in rubber, a review. Rubber Chem. Technol. 69(3), 424–443 (1996)

Kasner, A.I., Meinecke, E.A.: Effect of porosity on dynamic mechanical properties of rubber in compression. Rubber Chem. Technol. 69(2), 223–233 (1996)

Griffith, A.A.: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. A 221, 163–198 (1921)

Stoll, R.D., Freudenthal, A.M., Heller, R.A.: Effects of mean pressure on the behavior of a filled elastomer. Exp. Mech. 7(9), 339–345 (1967)

Buswell, H.J.: The effect of pressure on the flow properties of filled polyisobutylene. Rheol. Acta 13(3), 571–576 (1974)

Oberth, A.E.: Principle of strength reinforcement in filled polymers. Rubber Chem. Technol. 40, 1337–1362 (1967)

Blatz, P.J., Sharda, S.C., Tschoegl, N.W.: Strain energy function for rubberlike materials based on a generalized measure of strain. Trans. Soc. Rheol. 18(1), 145–161 (1974)

Beatty, M.F.: Topics in finite elasticity: hyperelasticity of rubber, elastomers, and biological tissues-with examples. Appl. Mech. Rev. 40(12), 1699–1734 (1987)

Boyce, M.C., Arruda, E.M.: Constitutive models of rubber elasticity: a review. Rubber Chem. Technol. 73(3), 504–523 (2000)

Warren, N.: Theoretical calculation of the compressibility of porous media. J. Geophys. Res. 78(2), 352–362 (1973)

Tobolsky, A.V., Shen, M.C.: Thermoelasticity, chain conformation, and the equation of state for rubber networks. J. Appl. Phys. 37(5), 1952–1955 (1966)

Misra, A., Singh, V.: Thermomechanics-based nonlinear rate-dependent coupled damage-plasticity granular micromechanics model. Continuum Mech. Thermodyn. 27(4–5), 787–817 (2015)

Jia, H., Misra, A., Poorsolhjouy, P., Liu, C.: Optimal structural topology of materials with micro-scale tension-compression asymmetry simulated using granular micromechanics. Mater. Des. 115, 422–432 (2017)

Timofeev, D., Barchiesi, E., Misra, A., Placidi, L.: Hemivariational continuum approach for granular solids with damage-induced anisotropy evolution. Math. Mech. Solids 26(5), 738–770 (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Andreas Öchsner.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This research was performed along the graduate studies of the author at the University of Southern California, LA, USA, under the supervision of professor P.J. Blatz (passed away on May 2010).

Rights and permissions

About this article

Cite this article

Kakavas-Papaniaros, P.A., Giannopoulos, G.I. Nonlinear analysis for propellant solids. Continuum Mech. Thermodyn. 34, 1159–1171 (2022). https://doi.org/10.1007/s00161-022-01111-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00161-022-01111-w