Abstract

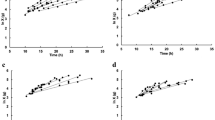

Growth kinetics ofSaccharomyces cerevisiae in glucose syrup from cassava starch and sugarcane molasses were studied using batch and fed-batch cultivation. The optimum temperature and pH required for growth were 30°C and pH 5.5, respectively. In batch culture the productivity and overall cell yield were 0.31 g L−1 h−1 and 0.23 g cells g−1 sugar, respectively, on glucose syrup and 0.22 g L−1 h−1 and 0.18 g cells g−1 sugar, respectively, on molasses. In fed-batch cultivation, a productivity of 3.12 g L−1 h−1 and an overall cell yield of 0.52 g cells g−1 sugar in glucose syrup cultivation and a productivity of 2.33 g L−1 h−1 and an overall cell yield of 0.46 g cells g−1 sugar were achieved in molasses cultivation by controlling the reducing sugar concentration at its optimum level obtained from the fermentation model. By using an on-line ethanol sensor combined with a porous Teflon® tubing method in automating the feeding of substrate in the fed-batch culture, a productivity of 2.15 g L−1 h−1 with a yield of 0.47 g cells g−1 sugar was achieved using glucose syrup as substrate when ethanol concentration was kept at a constant level by automatic control.

Similar content being viewed by others

References

Agrawal P, G Koshy and M Ramseier. 1989. An algorithm for oprating a fed-batch fermenter at optimum specific-growth rate. Biotechnol Bioeng 33: 115–125.

Aiba S, S Nagai and Y Nishizawa. 1976. Fed-batch culture ofSaccharomyces cerevisiae: a perspective of computer control to enhance the productivity in baker's yeast cultivation. Biotechnol Bioeng 18: 1001–1016.

Cooney CL, HY Wang and DIC Wang. 1977. Computer-aided material balancing for production of fermentation parameters. Biotechnol Bioeng 19:55–67.

Dairaku K and T Yamane. 1979. Use of porous teflon tubing method to measure gaseous or volatile substances dissolved in fermentation liquids. Biotechnol Bioeng 21:1671–1676.

Fatimah AB, A Arbakariya and AB Fadzilla. 1992. Growth kinetics study of bakers' yeast (Saccharomyces cerevisiae). ASEAN Food J 7: 205–206.

Miller GL. 1959. Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31: 426–428.

Reed G. 1982. Production of baker's yeast. In: Prescott and Dunn's Industrial Microbiology. 4th edn, pp 593–633, AVI Publishing Co, Westport, CT.

Somogyi M. 1945. A new reagent for the determination of sugars. J Biol Chem 61: 160.

Wang HY, CL Cooney and DIC Wang (1979) Computer control of baker's yeast production. Biotechnol Bioeng 21: 975.

Yamane T, M Matsuda and E. Sada. 1981. Application of porous teflon tubing method to automatic fed-batch culture of micro-organisms. I. Automatic constant-value control of fed substrate (ethanol) concentration in semibatch culture of yeast. Biotechnol Bioeng 23: 2509–2524.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Win, S.S., Impoolsup, A. & Noomhorm, A. Growth kinetics ofSaccharomyces cerevisiae in batch and fedbatch cultivation using sugarcane molasses and glucose syrup from cassava starch. Journal of Industrial Microbiology 16, 117–123 (1996). https://doi.org/10.1007/BF01570071

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF01570071