Abstract

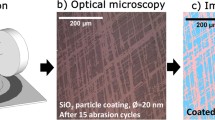

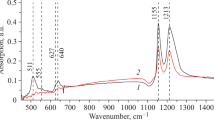

Semi-gloss commerical poly(vinylidene fluoride) (PVDF) coatings typically have 60° gloss values between 20 and 50. Gloss is affected by PVDF crystallite structures and by the pigmentation. In this article, we have demonstrated that for some pigmented PVDF coatings, after 10 years of Florida exposure, the principal proximal cause of gloss changes is the formation of micron-scale pits, rather than the emergence of pigment particles at the coating surface. We have used laser scanning confocal microscopy (LSCM) and light scattering to characterize the surface topography and near-surface structure of weathered and unweathered PVDF coatings. Florida-weathered PVDF coatings show only a modest increase in the root mean square (RMS) roughness of the surface, even when oticeable gloss loss has occurred. Changes in gloss can be correlated with surface roughness and other topographical, features, including the formation of pits and the emergence of pigments.

Similar content being viewed by others

References

Iezzi, R.A., “Fluoropolymer Coatings for Architectural Application,” Modern Fluoropolymers, John Wiley & Sons Chap. 14, 271, 1997.

See for instance Nguyen, T., et al., “Relating Laboratory and Outdoor Exposure of Coatings: II. Effects of Relative Humidity on Photodegradation and the Apparent Quantum Yield of Acrylic-Melamine Coatings,” J. Coat. Technol., 74, No. 932, 65 (2002), and a number of articles in Bauer, D.R. and Martin, J.W. (Eds.), Service Life Prediction: Methodology and Metrologies, ACS Symposium, Series 805, 2002.

Wood, K.A., Cypcar, C., and Hedhli, L., “Predicting the Exterior Durability of New Fluoropolymer Coatings,” J. Fluorine Chem., 104, 63 (2004).

Corle, T.R. and Kino, G.S., “Confocal Scanning Optical Microscopy and Related Imaging Systems,” Academic Press, pp. 37–39, 1996.

Sung, L.P., Garver, J., Embree, E., Dickens, B., and Martin, J.W., “A Novel Light Scattering Instrument for Characterizing Polymeric Coating Materials,” NIST Internal Report (2006).

Colling, J.H. and Dunderdale, J., “The Durability of Paint Films Containing Titanium Dioxide—Contraction, Erosion and Clear Layer Theories,” Prog. Org. Coat., 9, 47 (1981).

Braun, J.H., “Titanium Dioxide’s Contribution to the Durability of Paint Films,” Prog. Org. Coat. 15, 249 (1987).

VanLandingham, M.R., Nguyen, T., Byrd, W.E., and Martin, J.W., “On the Use of the Atomic Force Microscope to Monitor Physical Degradation of Polymeric Coating Surfaces,” J. Coat. Technol., 73, No. 923, 43 (2001).

Nguyen, T., Gu, X., VanLandingham, M.R., Byrd, W.E., Martin D., Ryntz, R., and Martin, J.W., “Degradation Modes of Polymeric Coatings Exposed to UV,” Proc. 7th International Coatings for Plastics Symposium, Troy, MI, June 2004.

Faucheu, J. and Wood, K. A., Proc. 3rd International Symposium on Service Life Prediction of Coatings, Sedona AZ, February 2004.

Biggs, S., Lukey, C.A., Spinks, G.M., and Yau, S.-T., “An Atomic Force Microscopy Study of Weathering of Polyester/Melamine Paint Surfaces,” Prog. Org. Coat. 42, 49 (2001).

Wood, K.A., Hedhli, L., and Willcox, P.J., “Patterns of Erosion from Acrylic and Fluoropolymer Coatings in Accelerated and Natural Weathering Tests,” J. Coat. Technol., 74, No. 924, 63 (2002).

Gu, X., Sung, L., Ho, D.L., Michaels, C.A., Nguyen, D., Jean, Y.C., and Nguyen, T., “Surface and Interface Properties of PVDF/Acrylic Copolymer Blends Before and After UV Exposure,” Proc. 80th Annual Meeting of the Federation of Societies for Coatings Technology, Oct. 30–Nov. 1, New Orleans, IA, 2002.

Alexander-Katz, R. and Barrera, R.G., “Surface Correlation Effects on Gloss,” J. Polym. Sci. Part B: Polym. Phys., Vol. 36, 1321 (1998).

Whitehouse, D.J., Bowen, D.K., Venkatesh, V.C., Lonardo, P., and Brown, C.A., “Gloss and Surface Topography,” Annals of the CIRP, Vol. 43, 541 (1994).

Assender, H., Bliznyuk, V., and Porfyrakis, K., “How Surface Topography Relates to Materials’ Properties,” Science, Vol. 297, 973 (2002).

Johnson, M.A. and Cote, P.J., “Detrended Fluctuation Analysis of UV Degradation in a Polyurethane Coating,” J. Coat Technol., 75, No. 941, 51 (2003).

Ginneken, B.V., Stavridi, M., and Koendrink, J.J., “Diffuse and Specular Reflectance from Rough Surface,” Appl. Opt., 37, 1, p. 130 (1998).

Braun, J.H., “White Pigments,” Federation Series on Coatings Technology, FSCT, Blue Bell, PA, 1995.

Falla, N., Surf. Coat. International 81 (8), 375–380 (1998).

Hunt, F.Y., Galler, M.A., and Martin, J.W., “Microstructure of Weathered Pain and Its Relation to Gloss Loss: Computer Simulation and Modelling,” J. Coat. Technol., 70, No. 880, 45 (1998).

The NIH freeware ImageJ can be downloaded from http://rsb.info.nih.gov/ij/.

Bentz, D.P., “Quantitative Comparison of Real CEMHYD3D Model Microstructures Using Correlation Functions,” in press, Cement and Concrete Research (2006).

The current output at each port of the 2-meter-Integrating SPHERE is about 22 “sun”—Intensity of 1 “sun” is equal to 22 W/m2 (ASTM E891) and is rich in the region between 290 nm and 400 nm. For technical information: Chin, J.W., Byrd, E., Embree, N., Martin, J., and Tate, J.D., “Ultraviolet Chambers Based on Integrating Spheres for Use in Artificial Weathering,” J. Coat. Technol., 74, No. 929, 39 (2002).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Faucheu, J., Wood, K.A., Sung, LP. et al. Relating gloss loss to topographical features of a PVDF coating. J Coat. Technol. Res. 3, 29–39 (2006). https://doi.org/10.1007/s11998-006-0003-8

Issue Date:

DOI: https://doi.org/10.1007/s11998-006-0003-8