Abstract

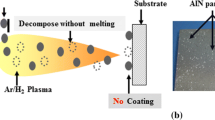

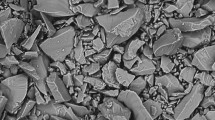

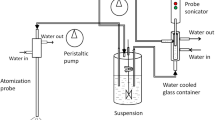

Fabrication of aluminum nitride (AlN) coatings using conventional plasma spraying processes directly has been deemed impossible. It is attributed to the thermal decomposition of the AlN feedstock particles during spraying without a stable melting phase. Using the reactivity of the plasma (reactive plasma spraying: RPS) showed a promising consideration for in situ formation of AlN thermally sprayed coatings. Several AlN-based coatings were fabricated through the RPS of aluminum powders in the N2/H2 plasma. The focus of this study is in discussing the morphology of splat deposition during the nitriding of Al particles. Furthermore, the influence of the feeding rate during the RPS and nitriding of Al powders will be investigated. The nitride content, as well as the unreacted molten Al phase, strongly influences splat deposition and morphology during the RPS of Al. The collected splats can be divided into reacted, partially reacted, and unreacted splats. The reacted splats tend to show a disk or egg-shell shape. The partially reacted mainly had outside nitride shells and an unreacted molten Al part in the center. The unreacted splats tended to show a splash shape. The main controlling factor is the time of the droplet impact on the substrate during the reaction sequence. The particle size and spray distance showed significant effects on the splat formation due to their effect on the nitriding conversion and the melting behavior of the particles during RPS nitriding. The powder feeding rate was investigated through increasing the injection rate and by using a low carrier gas flow rate. Increasing the powder feeding rate significantly improved the coating thickness. However, it suppressed the nitriding conversion of the large Al particles. Thus, with increasing the amount of the powder in the plasma, the Al molten particles are easily aggregated and agglomerate together upon colliding on the substrate with an AlN shell on the surface. This prevents the N2 from having access to all of the aggregated particles. Therefore, the fabricated coatings using large Al particles consist of surface AlN layers and the central parts of AlN and Al composite layers. On the other hand, it was possible to fabricate about 500-μm-thick AlN coatings using fine Al particles of 15 μm and increasing the feeding rate. Using the fine particles improved the nitriding reaction due to the improvement of the surface area (the reaction area). Moreover, the nitriding process of the Al particles with increasing the feeding rate was also investigated.

Similar content being viewed by others

References

H.O. Pierson, Handbook of Refractory Carbides and Nitrides, Noyes, New Jersey, USA, 1996, p 237-239

A.W. Wemer, Carbide, Nitride and Boride Materials Synthesis and Processing, Chapman & Hall, London, 1997, p 6-68

S. Nakamura, The Roles of Structural Imperfections in InGaN-Based Blue Light-Emitting Diodes and Laser Diodes, Science, 1998, 281, p 956-961

M. Fukumoto, M. Yamada, T. Yasui, and K. Takahashi, Fabrication of Aluminum Nitride Coating by Reactive RF Plasma Spray Process, Proc. International Thermal Spray Conference (ITSC), 2004, CD.

M. Yamada, T. Yasui, M. Fukumoto, and K. Takahashi, Nitridation of Aluminum Particles and Formation Process of Aluminum Nitride Coatings by Reactive RF Plasma Spraying, Thin Solid Films, 2007, 515(9), p 4166-4171

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Cubic Aluminum Nitride Coating Through Atmospheric Reactive Plasma Nitriding, J. Therm. Spray Technol., 2010, 19(3), p 635-641

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Fabrication of AlN Coatings by Reactive Atmospheric Plasma Spray Nitriding of Al Powders, Mater. Trans., 2010, 51(5), p 957-961

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Atmospheric Plasma Spraying of AlN Coatings: Influence of Aluminum Feedstock Particle Size, J. Therm. Spray Technol., 2011, 20(3), p 580-589

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Controlling of Nitriding Process on Reactive Plasma Spraying of Al Particles, IOP Conference Series: Mater. Sci. Eng., 2011, 18, 202006. doi: 10.1088/1757-899X/18/20/202006.

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Influence of Plasma Gases on Fabrication of AlN Coatings Through Atmospheric Plasma Nitriding Process, Ind. Appl. Plasma Process, 2010, 3, p 1-10

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Influence of NH4Cl Powder Addition for Fabrication of Aluminum Nitride Coating in Reactive Atmospheric Plasma Spray Process, J. Therm. Spray Technol., 2011, 20(1-2), p 205-212

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, In situ Fabrication of AlN Coating by Reactive Plasma Spraying of Al/AlN Powder, Coatings, 2011, 1-2, p 88-107

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Synthesis of Cubic Aluminum Nitride Coating from Al2O3 Powder in Reactive Plasma Spray Process, Mater. Trans., 2013, 54(2), p 207-214

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, N2 and H2 Plasma Gases’ Effects in Reactive Plasma Spraying of Al2O3 Powder, Surf. Coat. Technol., 2013, 216, p 308-317

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Plasma Spraying of Fine Al2O3/AlN Feedstock Powder, J. Therm. Spray Technol., 2013, 22(8), p 1283-1293

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Plasma Sprayed Aluminum Nitride Based Coating Thermal Conductivity, J. Therm. Spray Technol., 2015, 24(8), p 1385-1398

P. Fauchais, M. Fukumoto, A. Vardelle, and M. Vrdelle, Knowledge Concerning Splat Formation: An Invited Review, J. Therm. Spray Technol., 2004, 13(3), p 337-360

M. Fukumoto, I. Ohgitani, and T. Yasui, Effect of Substrate Surface Change on Flattening Behaviour of Thermal Sprayed Particles, Mater. Trans., 2004, 45(6), p 1869-1873

M. Fukumoto, I. Ohgitani, Y. Tanaka, and E. Nishioka, Flattening Problem of Thermal Sprayed Particles, Mater. Sci. Forum, 2004, 449(452), p 1309-1312

P. Fauchais, A. Vardelle, and B. Dussoubs, Quo Vadis Thermal Spraying?, J. Therm. Spray Technol., 2001, 10(1), p 44-66

P. Fauchais, G. Montavan, and G. Bertrand, Influence of Powders on Thermal Spray Coating Structures: Recent Developments in Nano or Finely Structured Coatings and Some Safety Issues, Proc. International Thermal Spray Conference (ITSC), 2009, p 799-817.

M. Vardelle, A. Vardelle, P. Fauchais, K.-I. Li, B. Dussoubs, and N.J. Themelis, Controlling Particle Injection in Plasma Spraying, J. Therm. Spray Technol., 2001, 10(2), p 267-284

V. Rosenband and A. Gany, Activation of Combustion Synthesis of Aluminium Nitride Powder, J. Mater. Process. Technol., 2004, 147, p 179-203

T. Fujii, K. Yoshida, K. Suzuki, and S. Ito, Direct Nitriding of Large Grains of Aluminum with 2 mm Size, Solid State Ionics, 2001, 141-142, p 593-598

K. Remesh, H.W. Ng, and S.C.M. Yu, Influence of Process Parameters on the Deposition Footprint in Plasma-Spray Coating, J. Therm. Spray Technol., 2003, 12, p 377-392

C. Lin and S. Chung, Combustion Synthesis of Aluminum Nitride Powder Using Additives, J. Mater. Research, 2001, 16(8), p 2200-2208

Y. Qiu and L. Gao, Nitridation Reaction of Aluminium Powder in Flowing Ammonia, J. Eur. Ceram. Soc., 2003, 23, p 2015-2022

M. Radwan and M. Bahgat, A Modified Direct Nitridation Method for Formation of Nano-AlN Wiskers, J. Mater. Process. Technol., 2007, 181, p 99-105

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 7th Asian Thermal Spray Conference (ATSC 2015) and has been expanded from the original presentation. ATSC 2015 was held in Xi’an, China, during September 23-25, 2015, and was organized by the Asian Thermal Spray Society in association with Xi’an Jiaotong University, State Key Laboratory for Mechanical Behavior of Materials.

Rights and permissions

About this article

Cite this article

Shahien, M., Yamada, M. & Fukumoto, M. Splat Morphology and Influence of Feeding Rate During Reactive Plasma Spray of Aluminum Powder. J Therm Spray Tech 25, 1490–1501 (2016). https://doi.org/10.1007/s11666-016-0417-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0417-5