Abstract

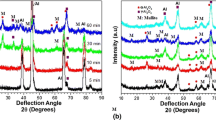

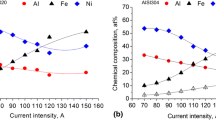

Recently, thick aluminum nitride/alumina (AlN/Al2O3) composite coatings were successfully fabricated through the reactive plasma spraying of fine Al2O3/AlN mixture in the N2/H2 atmospheric plasma. The coatings consist of AlN, Al5O6N, γ-Al2O3, and α-Al2O3 phases. This study will evaluate the thermal conductivity of these complicated plasma-sprayed coatings and optimize the controlling aspects. Furthermore, the influence of the process parameters on the coatings thermal conductivity will be investigated. The fabricated coatings showed very low thermal conductivity (2.43 W/m K) compared to the AlN sintered compacts. It is attributed to the phase composition of the fabricated coatings, oxide content, and porosity. The presence of Al2O3, Al5O6N and the high coating porosity decreased its thermal conductivity. The presence of oxygen in the AlN lattice creates Al vacancies which lead to phonon scattering and therefore suppressed the thermal conductivity. The formation of γ-Al2O3 phase in the coating leads to further decrease in its conductivity, due to its lower density compared to the α-phase. Moreover, the high porosity of the coating strongly suppressed the conductivity. This is due to the complicated microstructure of plasma spray coatings (splats, porosity, and interfaces, particularly in case of reactive spray process), which obviously lowered the conductivity. Furthermore, the measured coating density was lower than the AlN value and suppressed the coating conductivity. In addition, the spraying parameter showed a varied effect on the coating phase composition, porosity, density, and therefore on its conductivity. Although the N2 gas flow improved the nitride content, it suppressed the thermal conductivity gradually. It is attributed to the further increase in the porosity and further decrease in the density of the coatings with the N2 gas. Furthermore, increasing the arc did not show a significant change on the coating thermal conductivity. On the other hand, the influence of spray parameters was optimized by investigating the effect of simple heat treatment (at 1100 °C) as a function of the arc current and N2 gas flow. The heat treatment improved the coating thermal conductivity at the different spray parameters. Thus, after heat treatment, the coating porosity, γ-Al2O3, Al5O6N strongly decreased and therefore the conductivity improved. On the other hand, the N2 gas flow and/or arc current did not show any difference on the conductivity after heat treatment. Therefore, using higher N2 gas flow and higher arc current is economically useless. Finally, although the obtained conductivity of the coating was not so high (compared to the AlN value), the main factors that govern the conductivity of such complicated plasma-spraying composite coating was realized. Herein, in order to fabricate high thermal conductivity AlN plasma spray coating, adjusting the phase composition, oxide content, porosity, and microstructure (at low N2 gas flow rate and low arc current) through the post-heat treatment is the key factor.

Similar content being viewed by others

References

G. Selvaduray and L. Sheet, Aluminum Nitride: Review of Synthesis Methods, Mater. Sci. Technol., 1993, 9, p 463-473

H.O. Pierson, Handbook of Refractory Carbides and Nitrides, Noyes, Hammonton, 1996, p 237-239

A.W. Wemer, Carbide, Nitride and Boride Materials Synthesis and Processing, Chapman & Hall, London, 1997, p 6-68

E.I. Meletis and S. Yan, Formation of Aluminum Nitride by Intensified Plasma Ion Nitriding, J. Vac. Sci. Technol. A, 1991, 9(4), p 2279-2284

W.D. Kingery, H.K. Bowen, and D.R. Uhlmann, Introduction to Ceramic, Wiley, New York, 1976, p 583

J.-E. Sundgren, Structure and Properties of TiN Coatings, Thin Solid Films, 1985, 128, p 21-44

P. Fauchais, A. Vardelle, and B. Dussoubs, Quo Vadis Thermal Spraying?, J. Therm. Spray Technol., 2001, 10(1), p 44-66

M.F.O. Schiefler Filho, A.J.A. Buschinelli, F. Gärtner, A. Kirsten, J. Voyer, and H. Kreye, Influence of Process Parameters on the Quality of Thermally Sprayed X46Cr13 Stainless Steel Coatings, J. Braz. Soc. Mech. Sci. Eng., 2004, 26(1), p 98-106

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, In Situ Fabrication of AlN Coating by Reactive Plasma Spraying of Al/AlN Powder, Coatings, 2011, 1-2, p 88-107

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Atmospheric Plasma Spraying of AlN Coatings: Influence of Aluminum Feedstock Particle Size, J. Therm. Spray Technol., 2011, 20(3), p 580-589

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Influence of NH4Cl Powder Addition for Fabrication of Aluminum Nitride Coating in Reactive Atmospheric Plasma Spray Process, J. Therm. Spray Technol., 2011, 20(1-2), p 205-212

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Influence of Plasma Gases on Fabrication of AlN Coatings Through Atmospheric Plasma Nitriding Process, Ind. Appl. Plasma Process., 2010, 3, p 1-10

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Cubic Aluminum Nitride Coating Through Atmospheric Reactive Plasma Nitriding, J. Therm. Spray Technol., 2010, 19(3), p 635-641

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Fabrication of AlN Coatings by Reactive Atmospheric Plasma Spray Nitriding of Al Powders, Mater. Trans., 2010, 51(5), p 957-961

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, N2 and H2 Plasma Gases’ Effects in Reactive Plasma Spraying of Al2O3 Powder, Surf. Coat. Technol., 2013, 216, p 308-317

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Synthesis of Cubic Aluminum Nitride Coating from Al2O3 Powder in Reactive Plasma Spray process, Mater. Trans., 2013, 54(2), p 207-214

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Fabrication of AlN/Al2O3 Coatings via Atmospheric Reactive Plasma Nitriding of Al2O3 Powders, Key Eng. Mater., 2011, 484, p 166-171

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Plasma Spraying of Fine Al2O3/AlN Feedstock Powder, J. Therm. Spray Technol., 2013, 22(8), p 1283-1293

W.J. Parker, R.J. Jenkins, C.P. Butler, and G.L. Abbott, A Flash Method of Determining Thermal Diffusivity, Heat Capacity, and Thermal Conductivity, J. Appl. Phys., 1961, 32, p 1679-1684

JIS R1611, Measurement Methods of Thermal Diffusivity, Specific Heat Capacity, and Thermal Conductivity for Fine Ceramics by Flash Method, Japan Industrial Standards, Tokyo, 2010

ISO 18755, Fine Ceramics (Advanced Ceramics, Advanced Technical Ceramics)—Determination of Thermal Diffusivity of Monolithic Ceramics by Laser Flash Method, International Organization for Standardization, Geneva, 2005

M.J. O’Neill, Measurement of Specific Heat Functions by Differential Scanning Calorimetry, Anal. Chem., 1966, 38(10), p 1331-1336

JIS R1672, Determination of Specific Heat of Fiber-Reinforced Ceramics Composite by Differential Scanning Calorimetry Methods, Japan Industrial Standards, Tokyo, 2006

JIS K 7123, Testing Methods for Specific Heat Capacity of Plastics, Japan Industrial Standards, Tokyo, 1987

F.Y.C. Boey, X.L. Song, Z.Y. Gu, and A. Tok, AlON Phase Formation in a Tape-Cast Al2O3/AlN Composite, J. Mater. Proces. Technol., 1999, 89(90), p 478-480

G.A. Slack, Nonmetallic Crystals with High Thermal Conductivity, J. Phys. Chem. Solids, 1973, 34(2), p 321-335

G.A. Slack, R.A. Tanzilli, R.O. Pohl, and J.W. Vandersande, The Intrinsic Thermal-Conductivity of AlN, J. Phys. Chem. Solids, 1987, 48(7), p 641-647

A.V. Virkar, T.B. Jackson, and R.A. Cutler, Thermodynamic and Kinetic Effects of Oxygen Removal on the Thermal Conductivity of Aluminum Nitride, J. Am. Ceram. Soc., 1989, 72(11), p 2031-2042

N.N. Ault, Characteristics of Refractory Oxide Coatings Produced by Flame-Spraying, J. Am. Ceram. Soc., 1957, 40, p 69-74

G.F. Hurley and F.D. Gac, Structure and Thermal Diffusivity of Plasma-Sprayed Al2O3, Am. Ceram. Soc. Bull., 1979, 58(5), p 509-511

K.S. Ravichandran, K. An, R.E. Dutton, and S.L. Semiatin, Thermal Conductivity of Plasma-Sprayed Monolithic and Multilayer Coatings of Alumina and Yttria-Stabilized Zirconia, J. Am. Ceram. Soc., 1999, 82(3), p 673-682

S. Boire-Lavigne, C. Moreau, and R.G. Saintjacques, The Relationship Between the Microstructure and Thermal Diffusivity of Plasma-Sprayed Tungsten Coatings, J. Therm. Spray Technol., 1995, 4(3), p 261-267

S. Raghavan, H. Wang, R.B. Dinwiddie, W.D. Porter, and M. Mayo, Effect of Grain Size, Porosity and Yttria Content on the Thermal Conductivity of Nanocrystalline Zirconia, Scr. Mater., 1998, 39(8), p 1119-1125

L.H. Cao, K.A. Khor, L. Fu, and F. Boey, Plasma Spray Processing of Al2O3/AlN Composite Powders, J. Mater. Process. Technol., 1999, 89(90), p 392-398

R.J. Damani and P. Makroczy, Heat Treatment Induced Phase and Microstructural Development in Bulk Plasma Sprayed Alumina, J. Eur. Ceram. Soc., 2000, 20(7), p 867-888

Acknowledgments

This research was supported by the Grants-in-Aid for JSPS Fellows (232575) of Japan Society for the Promotion of Science (JSPS).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shahien, M., Yamada, M., Fukumoto, M. et al. Reactive Plasma-Sprayed Aluminum Nitride-Based Coating Thermal Conductivity. J Therm Spray Tech 24, 1385–1398 (2015). https://doi.org/10.1007/s11666-015-0314-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0314-3