Abstract

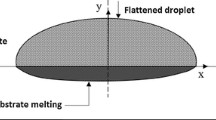

Millimeter-sized molten Cu droplets were deposited on AISI304 substrate surface by free falling experiment. The roles of substrate temperature and ambient pressure on heat transfer at interface between molten droplet and substrate surface were systematically investigated. The splat characteristics were evaluated in detail. Temperature history of molten droplet was measured at splat-substrate interface. Cooling rate of the flattening droplet was calculated as well. Furthermore, the spreading behavior of molten droplet on substrate surface was captured by high speed camera. The heat transfer from splat to substrate was enhanced both by substrate heating and by ambient pressure reduction, which can be attributed to the good contact at splat bottom surface. The splats in free falling experiment showed similar changing tendency as thermal-sprayed particles. Consequently, substrate temperature and ambient pressure have an equivalent effect to contact condition at interface between droplet and substrate surface. Substrate heating and pressure reduction may enhance the wetting during splat flattening, and then affect the flattening and solidification behavior of the molten droplet.

Similar content being viewed by others

References

M.L. Thorpe, Thermal Spray Industry in Transition, Adv. Mater. Process, 1993, 143(5), p 50-61

F. Kassabji, G. Jacq, and J.P. Durand, Thermal Spray Applications for the Next Millenium: A Business Development Perspective, Proceedings of the International Thermal Spraying Conference 1998, C. Coddet, Ed., May 25-29, 1998 (Nice, France), ASM International, Materials Park, OH, 1998, p 1677-1680

M. Ducos and J.P. Durand, Thermal Coatings in Europe, Business Prospection, Proceedings of the International Thermal Spraying Conference 2001, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 25-29, 2001 (Singapore), ASM International, Materials Park, OH, 2001, p 1267-1271

M. Fukumoto, H. Hayashi, and T. Yokoyama, Relationship Between Particle’s Splat Pattern and Coating Adhesive Strength of HVOF Sprayed Cu-Alloy, J. Jpn. Therm. Spray Soc., 1995, 32(3), p 149-156 (in Japanese)

M. Fukumoto, S. Katoh, and I. Okane, Splat Behavior of Plasma Sprayed Particles on Flat Substrate Surface, Proceedings of the International Thermal Spray Conference 1995, A. Ohmori, Ed., May 22-26, 1995 (Kobe, Japan), ASM International, Materials Park, OH, 1995, p 353-358

M. Fukumoto, K. Yang, T. Yasui, and M. Yamada, Control of Thermal Spray Process through Observation on Individual Splat Behavior, J. Solid Mech. Mater. Eng., 2010, 4(2), p 107-118

M. Vardelle, A. Vardelle, A.C. Leger, P. Fauchais, and D. Gobin, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol., 1995, 4(1), p 50-58

K. Yang, K. Tomita, M. Fukumoto, M. Yamada, and T. Yasui, Effect of Ambient Pressure on Flattening Behavior of Thermal Sprayed Particles, J. Therm. Spray Technol., 2009, 18(4), p 510-518

M. Fukumoto, Y. Tanaka, and E. Nishioka, Flattening Problem of Thermal Sprayed Particles, Mater. Sci. Forum, 2004, 449-452, p 1309-1312

M. Fukumoto, M. Shiiba, H. Kaji, and T. Yasui, Three-Dimensional Transition Map of Flattening Behavior in the Thermal Spray Process, Pure Appl. Chem., 2005, 77(2), p 429-442

M. Fukumoto, T. Yamaguchi, M. Yamada, and T. Yasui, Splash Splat to Disk Splat Transition Behavior in Plasma-Sprayed Metallic Materials, J. Therm. Spray Technol., 2007, 16(5-6), p 905-912

J. Madjeski, Solidification of Droplets on a Cold Surface, Int. J. Heat Mass Transf., 1976, 19, p 1009-1013

H. Fukanuma, A Porosity Formation Flattening Model of an Impinging Molten Particle in Thermal Spray Coatings, J. Therm. Spray Technol., 1994, 3(1), p 33-44

R. Dhiman, A. McDonald, and S. Chandra, Predicting Splat Morphology in a Thermal Spray Process, Surf. Coat Technol., 2007, 201, p 7789-7801

S. Chandra and P. Fauchais, Formation of Solid Splats During Thermal Spray Deposition, J. Therm. Spray Technol., 2009, 18(2), p 148-180

A.T.T. Tran, S. Brossard, M.M. Hyland, B.J. James, and P. Munroe, Evidence of Substrate Melting of NiCr Particles on Stainless Steel Substrate by Experimental Observation and Simulations, Plasma. Chem. Plasma Process., 2009, 29, p 475-495

C. Moreau, P. Gougeon, and M. Lamontagne, Influence of Substrate Preparation on the Flattening and Cooling of Plasma-Sprayed Particles, J. Therm. Spray Technol., 1995, 4(1), p 25-33

V. Pershin, M. Lufitha, S. Chandra, and J. Mostaghimi, Effect of Substrate Temperature on Adhesion Strength of Plasma-Sprayed Nickel Coatings, J. Therm. Spray Technol., 2003, 12(3), p 370-376

A. McDonald, C. Moreau, and S. Chandra, Effect of Substrate Oxidation on Spreading of Plasma-Sprayed Nickel on Stainless Steel, Surf. Coat Technol., 2007, 202, p 23-33

K. Yang, T. Usami, Y. Ebisuno, K. Tanaka, M. Fukumoto, T. Yasui, and M. Yamada, Study of Wetting on Flattening Behavior of Thermal Sprayed Particles, Proceedings of the 4th Asian Thermal Spray Conference (ATSC2009), chaired by C.J. Li, October 22-24, 2009 (Xi’an, China), p 226-231

C. Mundo, M. Sommerfeld, and C. Tropea, Droplet-Wall Collisions: Experimental Studies of the Deformation and Breakup Process, Int. J. Multiphase Flow, 1995, 21(2), p 151-173

P. Fauchais, M. Fukumoto, A. Vardelle, and M. Vardelle, Knowledge Concerning Splat Formation: An Invited Review, J. Therm. Spray Technol., 2004, 13(3), p 337-360

C. Escure, M. Vardelle, A. Vardelle, and P. Fauchais, Visualization on the Impact of Drops on a Substrate in Plasma Spraying: Deposition and Splashing Modes, Proceedings of the International Thermal Spraying Conference 2001, C.C. Berndt, K.A. Khor, and E.F. Lugscheider, Ed., May 25-29, 2001 (Singapore), ASM International, Materials Park, OH, 2001, p 805-812

H. Li, S. Costil, H.L. Liao, C.J. Li, M. Planche, and C. Coddet, Effects of Surface Conditions on the Flattening Behavior of Plasma Sprayed Cu Splats, Surf. Coat Technol., 2006, 200, p 5435-5446

M. Fukumoto, E. Nishioka, and T. Matsubara, Flattening and Solidification Behavior of a Metal Droplet on a Flat Substrate Surface Held at Various Temperatures, Surf. Coat Technol., 1999, 120-121, p 131-137

Y. Heichal and S. Chandra, Predicting Thermal Contact Resistance Between Molten Metal Droplets and a Solid Surface, J. Heat Transf., 2005, 127, p 1269-1275

M. Pasandideh-Fard, S. Chandra, and J. Mostaghimi, A Three-Dimensional Model of Droplet Impact and Solidification, Int. J. Heat Mass Transf., 2002, 45, p 2229-2242

S.D. Aziz and S. Chandra, Impact, Recoil and Splashing of Molten Metal Droplets, Int. J. Heat Mass Transf., 2000, 43, p 2841-2857

R.G. Azar, Z. Yang, S. Chandra, and J. Mostaghimi, Impact of Molten Metal Droplets on the Tip of a Pin Projecting From a Flat Surface, Int. J. Heat Fluid Flow, 2005, 26, p 334-347

M. Pasandideh-Fard, R. Bhola, S. Chandra, and J. Mostaghimi, Deposition of Tin Droplets on a Steel Experiments Plate: Simulations and Experiments, Int. J. Heat Mass Transf., 1998, 41, p 2929-2945

Y. Tanaka, S. Yoshida, and R. Kawase, Effect of Impact Velocity and Preheated Substrate Temperature on Flattening and Solidifying Behavior of Free Falling Metal Droplet, J. Jpn. Therm. Spray Soc., 2010, 47(2), p 54-60, (in Japanese)

L. Battezzati and A.L. Greer, The Viscosity of Liquid Metals and Alloys, Acta Metall., 1989, 37(7), p 1791-1802

S.G.G. Stokes, On the Effect of the Internal Friction of Fluids on the Motion of Pendulums, Trans. Camb. Philos. Soc., 1851, 9, p 8-106

O. Reynolds, An Experimental Investigation of the Circumstances Which Determine Whether the Motion of Water Shall be Direct or Sinuous, and of the Law of Resistance in Parallel Channels, Philos. Trans. R. Soc., 1883, 174, p 935-982

N. Rott, Note on the History of the Reynolds Number, Annu. Rev. Fluid Mech., 1990, 22, p 1-11

Y. Heichal, S. Chandra, and E. Bordatchev, A Fast-Response Thin Film Thermocouple to Measure Rapid Surface Temperature Changes, Exp. Therm Fluid Sci., 2005, 30(2), p 153-159

M. Qu and A. Gouldstone, On the Role of Bubbles in Metallic Splat Nanopores and Adhesion, J. Therm. Spray Technol., 2008, 17(4), p 486-494

C.J. Li and J.L. Li, Transient Contact Pressure During Flattening of Thermal Spray Droplet and its Effect on Splat Formation, J. Therm. Spray Technol., 2004, 13(2), p 229-238

C.J. Li and J.L. Li, Evaporated-Gas-Induced Splashing Model for Splat Formation During Plasma Spraying, Surf. Coat Technol., 2004, 184, p 13-23

M. Qu, Y. Wu, V. Srinivasan, and A. Gouldstone, Observations of Nanoporous Foam Arising From Impact and Rapid Solidification of Molten Ni Droplets, Appl. Phys. Lett., 2007, 90, p 254101-1-254101-3

A.T.T. Tran and M.M. Hyland, The Role of Substrate Surface Chemistry on Splat Formation During Plasma Spray Deposition by Experiments and Simulations, J. Therm. Spray Technol., 2009, 19(1-2), p 11-23

V.E. Henrich and P.A. Cox, The Surface Science of Metal Oxides, Cambridge University Press, Cambridge, New York, 1994

A. McDonald, M. Lamontagne, C. Moreau, and S. Chandra, Impact of Plasma-Sprayed Metal Particles on Hot and Cold Glass Surfaces, Thin Solid Films, 2006, 514, p 212-222

A. McDonald, C. Moreau, and S. Chandra, Thermal Contact Resistance Between Plasma Sprayed Particles and Flat Surfaces, Int. J. Heat Mass Transf., 2007, 50, p 1737-1749

R.H.S. Winterton, Newton’s Law of Cooling, Contemp. Phys., 1999, 40(3), p 205-212

X. Jiang, Y. Wan, H. Herman, and S. Sampath, Role of Condensates and Adsorbates on Substrate Surface on Fragmentation of Impinging Molten Droplets During Thermal Spray, Thin Solid Films, 2001, 385, p 132-141

M. Fukumoto, H. Nagai, and T. Yasui, Influence of Surface Character Change of Substrate Due to Heating on Flattening Behavior of Thermal Sprayed Particles, J. Therm. Spray Technol., 2006, 15(4), p 759-764

R.N. Wenzel, Resistance of Solid Surfaces to Wetting by Water, Ind. Eng. Chem., 1936, 28(8), p 988-994

T. Uelzen and J. Muller, Wettability Enhancement by Rough Surfaces Generated by Thin Film Technology, Thin Solid Films, 2003, 434, p 311-315

S. Sampath and H. Herman, Rapid Solidification and Microstructure Development During Plasma Spray Deposition, J. Therm. Spray Technol., 1996, 5(4), p 445-456

Acknowledgments

The authors would like to acknowledge Mr. Y. Ebisuno and T. Matsuda for their assistance and valuable discussions in the experiments. This research was partially supported both by the Grant-in-Aid for Scientific Research of the Ministry of Education, Science, Culture and Sports in Japan, and by a special research fund in Toyohashi University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fukumoto, M., Yang, K., Tanaka, K. et al. Effect of Substrate Temperature and Ambient Pressure on Heat Transfer at Interface Between Molten Droplet and Substrate Surface. J Therm Spray Tech 20, 48–58 (2011). https://doi.org/10.1007/s11666-010-9537-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-010-9537-5