Abstract

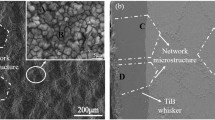

The oxidation behavior of Al2O3/TiAl in situ composites fabricated by hot-pressing technology was investigated at 900° in static air. The results indicate that the mass gains of the composites samples decrease gradually with increasing Nb2O5 content and the inert Al2O3 dispersoids effectively increase the oxidation resistance of the composites. The higher the Al2O3 dispersoids content, the more pronounced the effect. The primary oxidation precesses obey approximately the linear laws, and the cyclic oxidation precesses follow the parabolic laws. The oxidized sample containing Ti2AlN and TiAl phases in the scales exhibits excellent oxidation resistance. The oxide scale formed after exposure at 900°C for 120 h is multiple-layered, consisting mainly of an outer TiO2 layer, an intermediate Al2O3 layer, and an inner TiO2+Al2O3 mixed layer. From the outer layer to the inner layer, TiO2+Al2O3 mixed layer presents the transit of Al-rich oxide to Ti-rich oxide mixed layer. Near the substrate, cross-section micrograph shows a relatively loose layer, and micro- and macro-pores remain on this layer, which is a transition layer and transferres from Al2O3+TiO2 scale to substrate. The thickness of oxide layer is about 20 μm. It is also found that continuous protective alumina scales can not be observed on the surface of oxidation scales. Ti ions diffuse outwardly to form the outer TiO2 layer, while oxygen ions transport inwardly to form the inner TiO2+Al2O3 mixed layer. Under long-time intensive oxidation exposure, the internal Al2O3 scale has a good adhesiveness with the outer TiO2 scale. No obvious spallation of the oxide scales occurs. The increased oxidation resistance by the presence of in situ Al2O3 particulates is attributed to the enhanced alumina-forming tendency and thin and dense scale formation. Al2O3 particulates enhance the potential barrier of Ti ions from M/MO interface to O/MO interface, thereby the TiO2 growth rate decreases, which is also beneficial to improve the oxidation resistance. Moreover, the multi-structure of the TiO2+Al2O3 mixed layer decreases the indiffusion of oxygen ions and also avails to improve the high temperature oxidation resistance of the as-sintered composites.

Similar content being viewed by others

References

Kim Y W, Dimiduk D M. Progress in the understanding of gamma titanium aluminides. JOM, 1991, 43(8): 40–47

Dimiduk D M. Gamma titanium aluminide alloys-an assessment within the competition of aerospace structural materials. Mater Sci Eng A, 1999, 263: 281–288

Wu J, Jin H M, Zhang L W. Research progress on surface technology of TiAl intermetallics (in Chinese). Corros Sci Prot Tech, 2003, 15(1): 24–28

Dong L M, Cui Y Y, Yang R, et al. Effects of element Si on oxidation resistance of TiAl alloys (in Chinese). Acta Metall Sin, 2004, 40(4): 383–387

Zhou C G, Xu H B, Gong S K, et al. Cyclic oxidation behavior of TiAl and surface modification (in Chinese). Acta Aeronaut Astronaut Sin, 2000, 21(1): 79–89

Lu W, He L L. Oxidation and its microstructure investigation of high Nb-containing TiAl (in Chinese). J Chin Electron Microsc Soc, 2004, 23(4): 415–415

Zhang L, Xiao W H, Jiang H R. Morphology and formation of high-temperature oxide films of Ti-Al alloys (in Chinese). Chin J Nonferrous Met, 2006, 15(6): 899–903

Zhang Y G, Han Y F, Chen G L, et al. Structural Intermetallics (in Chinese). Beijing: National Defence Industry Press, 2001

Zhu Y C, Zhang Y, Li X Y, et al. The influence of magnetron-sputtered SiO2 coatings on the cyclic oxidation behavior of gamma-TiAl alloys. Mater Trans JIM (Jpn Inst Met), 2000, 41(9): 1118–1120

Nishimoto T, Izumi T, Hayashi S, et al. Two-step Cr and Al diffusion coating on TiAl at high temperatures. Intermetallics, 2003, 11(3): 225–235

Gauthier V, Dettenwanger F, Schutze M, et al. Oxidation-resistant aluminide coatings on γ-TiAl. Oxid Met, 2003, 59: 233–255

Xi Y J, Wang F H, He L L. Protective effect of the sputtered TiAl-CrAg coating on the high-temperature oxidation and hot corrosion resistance of Ti-Al-Nb alloy. J Mater Sci Technol, 2004, 20(6): 724–727

Li X Y, Taniguchi S, Zhu Y C, et al. Oxidation behavior of TiAl protected by Si+Nb combined ion implantation. Intermetallics, 2001, 9(5): 443–449

Yue Y L, Yin H Y, Qü Y, et al. Study on the oxidation properties of Ti2AlC/TiAl composites at high temperature (in Chinese). Rare Metal Mat Eng, 2007, 36(5): 853–856

Gao W L, Zhang H, Zhang E L, et al. Structure and formation mechanism of oxide scales of TiAl/TiB2 composites at high temperature (in Chinese). Rare Metal Mat Eng, 2006, 35(2): 209–212

Ai T T, Wang F, Zhu J F. Microstructure and mechanical properties of Al203/TiAl composite. T Nonferr Met Soc, 2006, 16(3): s1924–s1927

Wang F, Ai T T, Luo H J, et al. Analysis of strengthening mechanism in two-phase TiAl-based composites (in Chinese). J Aeronaut Mater, 2007, 27(3): 11–16

Qu H L, Zhou L, Wei H R. Interrupted oxidation kinetics of the TiAl alloys in static air (in Chinese). Rare Metal Mat Eng, 2000, 29(1): 8–12

Zhou Y C, Sun Z M. Electronic structure and bonding properties of layered machinable Ti2AlC and Ti2AlN ceramics. Phys Rev B, 2000, 61(19): 12570–12573

Tian W B, Wang P L, Zhang G J, et al. Progress of the layered Ternary Ceramics: M2AX (in Chinese). J Inorg Mater, 2007, 22(5): 783–790

Qu H L, Zhou L, Wei H R. Surface analyses of high-temperature oxidated TiAl-based alloys (in Chinese). Rare Metal Mat Eng, 2000, 29(2): 90–93

Qu H L, Zhou L, Wei H R, et al. Oxidation stratification of TiAl based alloy (in Chinese). Chin J Nonferrous Met, 2001, 11(3): 398–403

Zheng C L, Xu Z, He Z Y, et al. Progress in research on high temperature oxidation resistance of TiAl intermetallics (in Chinese). Mater Rev, 2002, 16(11): 14–16

Li X Y, Zhang Y G, Chen C Q, et al. Oxidation mechanism of binary Ti-Al alloys at elevated temperature (in Chinese). Acta Metall Sin, 1997, 33(9): 964–970

Qu H L, Zhou L, Wei H R. Oxidation behavior of TiAl alloys during thermal cycling (in Chinese). J Northeast Univ (Nat Sci), 2000, 21(4): 404–407

Shida Y, Anada H. Oxidation behavior of binary TiAl alloys in high temperature air environment. Mater Trans JIM (Jpn Inst Met), 1993, 34(3): 236–242

Li M S. The High Temperature Corrosion of Metals (in Chinese). Beijing: Metallurgical Industry Press, 2001

Taniguchi S, Shibata T. Influence of additional elements on the oxidation behaviour of TiAl. Intermetallics, 1996, 4(1): S85–S93

Taniguchi S, Tachikawa Y, Shibata T. Influence of oxygen partial pressure on the oxidation behaviour of TiAl at 1300K. Mat Sci Eng A-Sturct, 1997, 232(1–2): 47–54

Ikeda J A, Chiang Y M. Space charge segregation at grain boundaries in titanium dioxide: I, relationship between lattice defect chemistry and space potential. J Am Ceram Soc, 1993, 76: 2437–2446

Ikeda J A, Chiang Y M. Space charge segregation at grain boundaries in titanium dioxide: II, model experiments. J Am Ceram Soc, 1993, 76: 2447–2454

Haul R, Dumbgen G. Sauerstoff-selbstdiffusion in rutilkristallen. J Phys Chem Solids, 1965, 26(1): 1–10

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the Special Program for Education Bureau of Shaanxi Province, China (Grant No. 08JK240) and Scientific Research Startup Program for Introduced Talents of Shaanxi University of Technology, China (Grant No. SLGQD0751)

Rights and permissions

About this article

Cite this article

Ai, T., Wang, F. & Feng, X. High-temperature oxidation behavior of Al2O3/TiAl matrix composite in air. Sci. China Ser. E-Technol. Sci. 52, 1273–1282 (2009). https://doi.org/10.1007/s11431-008-0223-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-008-0223-5