Abstract

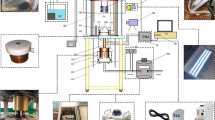

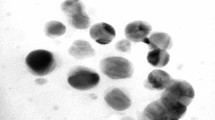

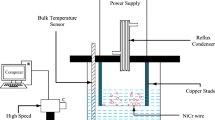

Past decades have seen active research in enhancement of boiling heat transfer by surface modifications. Favorable surface modifications are expected to enhance boiling efficiency. Several interrelated mechanisms such as capillarity, surface energy alteration, wettability, cavity geometry, wetting transitions, geometrical features of surface morphology, etc., are responsible for change in the boiling behavior of modified surfaces. Not much work is available on pool boiling at low pressures on microscale/nanoscale geometries; low pressure boiling is attractive in many applications wherein low operating temperatures are desired for a particular working fluid. In this background, an experimental setup was designed and developed to investigate the pool boiling performance of water on (a) plain aluminum micro wire (99.999 % pure) and, (b) nano-porous alumina structured aluminum micro wire, both having diameter of 250 µm, under sub-atmospheric pressure. Nano-structuring on the plain wire surface was achieved via anodization. Two samples, A and B of anodized wires, differing by the degree of anodization were tested. The heater length scale (wire diameter) was much smaller than the capillary length scale. Pool boiling characteristics of water were investigated at three different sub-atmospheric pressures of 73, 123 and 199 mbar (corresponding to T sat = 40, 50 and 60 °C). First, the boiling characteristics of plain wire were measured. It was noticed that at sub-atmospheric pressures, boiling heat transfer performance for plain wire was quite low due to the increased bubble sizes and low nucleation site density. Subsequently, boiling performance of nano-structured wires (both Sample A and Sample B) was compared with plain wire and it was noted that boiling heat transfer for the former was considerably enhanced as compared to the plain wire. This enhancement is attributed to increased nucleation site density, change in wettability and possibly due to enhanced pore scale evaporation. A preliminary estimation of the bubble growth rates, measured by high speed videography, was undertaken and compared with classical bubble growth rate correlations. It was observed that the average bubble departure sizes on Sample B were larger as compared to plain wire, due to larger surface forces holding the bubble before departure. Bubble condensation in the thermal boundary layer was also captured.

Similar content being viewed by others

Abbreviations

- A cs :

-

Cross-sectional area of wire (m2)

- A :

-

Surface area of wire (m2)

- D :

-

Diameter (m)

- g :

-

Gravitational acceleration (m/s2)

- h :

-

Heat transfer coefficient (W/m2 K)

- h fg :

-

Latent heat of vaporization (J/kg)

- L cr :

-

Capillary length scale (m)

- l :

-

Length (m)

- P :

-

Pressure (N/m2)

- \(q^{\prime \prime }\) :

-

Heat flux (W/m2)

- R :

-

Resistance (Ω)

- T :

-

Temperature (°C or K)

- α :

-

Temperature coefficient of resistance (K−1)

- δ :

-

Measurement uncertainty (−)

- \(\hat{\rho }\) :

-

Resistivity (Ω m)

- ρ :

-

Density (kg/m3)

- σ :

-

Surface tension (N/m)

- θ :

-

Contact angle (°)

- l, f :

-

Liquid

- v, g :

-

Vapor

- cr :

-

Critical

- o :

-

Initial

- sat :

-

Saturation

- w :

-

Wall

References

McGillis WR, Carey VP, Fitch JS, Hamburgen WR (1991) Pool boiling enhancement techniques for water at low pressure. In: Semiconductor thermal measurement management symposium, 1991, SEMI-THERM VII. Proceedings, seventh annual IEEE, pp 64–72

Kim J, Huh C, Kim MH (2007) On the growth behavior of bubbles during saturated nucleate pool boiling at sub-atmospheric pressure. Int J Heat Mass Transf 50(17):3695–3699

Yao Z, Lu Y-W, Kandlikar SG (2011) Effects of nanowire height on pool boiling performance of water on silicon chips. Int J Therm Sci 50(11):2084–2090

Zhang BJ, Kim KJ, Yoon H (2012) Enhanced heat transfer performance of alumina sponge-like nano-porous structures through surface wettability control in nucleate pool boiling. Int J Heat Mass Transf 55(25–26):7487–7498

Stutz B, Morceli CHS, Silva M, Cioulachtjian S, Bonjour J (2011) Influence of nanoparticle surface coating on pool boiling. Exp Therm Fluid Sci 35:1239–1249

Vemuri S, Kim KJ (2005) Pool boiling of saturated FC-72 on nano-porous surface. Int Commun Heat Mass Transf 32(1–2):27–31

Slomski EM, Fischer S, Herbert S, Oechsner M, Stephan P (2013) Textured CrN thin coatings enhancing heat transfer in nucleate boiling processes. Surf Coat Technol 215:465–471

Lee YC, Bhuiya MMH, Kim KJ (2010) Pool boiling heat transfer with nano-porous surface. Int J Heat Mass Transf 53(19):4274–4279

Ahn HS, Lee C, Kim H, Jo H, Kang S, Kim J, Kim MH (2010) Pool boiling CHF enhancement by micro/nanoscale modification of zircaloy-4 surface. Nucl Eng Des 240(10):3350–3360

Giancoli DC (1995) Physics: principles with applications, 4th edn. Prentice Hall, Upper Saddle River

Brandt R, Neuer G (2007) Electrical resistivity and thermal conductivity of pure aluminum and aluminum alloys up to and above the melting temperature. Int J Thermophys 28(5):1429–1446

Moffat RJ (1988) Describing the uncertainties in experimental results. Exp Therm Fluid Sci 1:3–17

Singh SK, Khandekar S, Pratap D, Ramakrishna SA (2013) Wetting dynamics and evaporation of sessile droplets on nano-porous alumina surfaces. Colloids Surf A Physicochem Eng Asp 432:71–81

Leese H, Bhurtun V, Lee KP, Mattia D (2013) Wetting behaviour of hydrophilic and hydrophobic nanostructured porous anodic alumina. Colloids Surf A Physicochem Eng Asp 420:53–58

Carey VP (1992) Liquid–vapor phase change phenomena, 2nd edn. Taylor & Francis, London

Van Stralen SJD, Cole R, Sluyter WM, Sohal MS (1975) Bubble growth rates in nucleate boiling of water at sub-atmospheric pressures. Int J Heat Mass Transf 18(5):655–669

Phan HT, Caney N, Marty P, Colasson S, Gavillet J (2009) Surface wettability control by nanocoating: the effects on pool boiling heat transfer and nucleation mechanism. Int J Heat Mass Transf 52(23–24):5459–5471

Fritz W (1935) Maximum volume of vapor bubble. Phys Z 36:379–384

Cornwell K, Nair BG, Patten TD (1976) Observation of boiling in porous media. Int J Heat Mass Transf 19(2):236–238

Chen L, Peterson GP (2007) Parametric study of pool boiling on horizontal highly conductive microporous coated surfaces. J Heat Transf 129(11):1465–1475

Forrest E, Williamson E, Buongiorno J, Hu LW, Rubner M, Cohen R (2010) Augmentation of nucleate boiling heat transfer and critical heat flux using nanoparticle thin-film coatings. Int J Heat Mass Transf 53(1–3):58–67

Huang C-K, Lee C-W, Wang C-K (2011) Boiling enhancement by TiO2 nanoparticle deposition. Int J Heat Mass Transf 54(23–24):4895–4903

Feng B, Keith W, Peterson GP (2012) Enhancement of critical heat flux in pool boiling using atomic layer deposition of alumina. Appl Phys Lett 100(5):053120 (1-3)

Cooper MG, Vijuk RM (1970) Bubble growth in nucleate pool boiling. In: Proceedings of 4th international heat transfer conference. Elsevier, Paris-Versailles, pp 1–11

El-Genk MS, Ali AF (2010) Enhanced nucleate boiling on copper micro-porous surfaces. Int J Multiph Flow 36(10):780–792

Hendricks TJ, Krishnan S, Choi C, Chang C-H, Paul B (2010) Enhancement of pool-boiling heat transfer using nanostructured surfaces on aluminum and copper. Int J Heat Mass Transf 53:3357–3365

Wu W, Bostanci H, Chow LC, Hong Y, Su M, Kizito JP (2010) Nucleate boiling heat transfer enhancement for water and FC-72 on titanium oxide and silicon oxide surfaces. Int J Heat Mass Transf 53(9–10):1773–1777

Jun S, Ray SS, Yarin AL (2013) Pool boiling on nano-textured surfaces. Int J Heat Mass Transf 62:99–111

Tang Y, Tang B, Li Q, Qing J, Lu L, Chen K (2013) Pool-boiling enhancement by novel metallic nanoporous surface. Exp Therm Fluid Sci 44:194–198

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arya, M., Khandekar, S., Pratap, D. et al. Pool boiling of water on nano-structured micro wires at sub-atmospheric conditions. Heat Mass Transfer 52, 1725–1737 (2016). https://doi.org/10.1007/s00231-015-1692-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-015-1692-2