Abstract

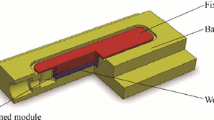

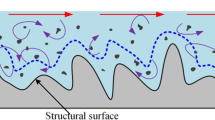

Soft abrasive flow (SAF) finishing has advantages in precise processing for the workpieces with tiny scale or irregular geometric surfaces. However, current SAF finishing methods have surface quality problem caused by uneven flow field profile. To resolve the problem, a novel double-inlet SAF finishing method is proposed based on the fluid collision theory. Taking two constrained processing apparatuses (single-inlet and double-inlet) as the objectives, in combination with the shear stress transport (SST) k-ω turbulence model, the fluid mechanic models for the two apparatuses are set up, and the preliminary abrasive flow field characteristics are acquired. Referring to the collision conservation principles, the profiles of dynamical pressure and turbulence intensity in double-inlet constrained passage are obtained. The simulated results show that the flow field distribution of single-inlet passage is in a steady state and non-uniform, a periodic oscillation phenomenon appears in double-inlet passage, and it can enhance the turbulence intensity and movement randomness of abrasive flow. The processing experiments show that the proposed SAF finishing method can make the roughness on parallel flowing direction less than 50 nm and can improve the finishing uniformity and efficiency.

Similar content being viewed by others

References

Zeng X, Ji SM, Jin MS, Tan DP, Ge JQ (2015) Research on dynamic characteristic of softness consolidation abrasives in machining process. Int J Adv Manuf Technol. doi:10.1007/s00170-015-7392-8

Nguyen T, Wang J, Li WY (2015) Process models for controlled-depth abrasive waterjet milling of amorphous glasses. Int J Adv Manuf Technol 77(5–8):1177–1189

Das M, Jain VK, Ghoshdastidar PS (2008) Analysis of magnetorheological abrasive flow finishing (MRAFF) process. Int J Adv Manuf Technol 38(5–6):613–621

Chen KY, Cheng KC (2014) A study of helical passageways applied to polygon holes in abrasive flow machining. Int J Adv Manuf Technol 74(5–8):781–790

Zeng X, Ji SM, Tan DP, Jin MS, Wen DH, Zhang L (2013) Softness consolidation abrasives material removal characteristic oriented to laser hardening surface. Int J Adv Manuf Technol 69(9–12):2323–2332

Rabani A, Marinescu I, Axinte D (2012) Acoustic emission energy transfer rate: a method for monitoring abrasive waterjet milling. Int J Mach Tool Manuf 61:80–89

Jang KI, Kim DY, Maeng S, Lee W, Han J, Seok J, Je TJ, Kang S, Min BK (2012) Deburring microparts using a magnetorheological fluid. Int J Mach Tool Manuf 53(1):170–175

Jain VK, Adsul SG (2000) Experimental investigations into abrasive flow machining (AFM). Int J Mach Tool Manuf 40(7):1003–1021

Das M, Jain VK, Ghoshdastidar PS (2012) Nanofinishing of flat workpieces using rotational-magnetorheological abrasive flow finishing (R-MRAFF) process. Int J Adv Manuf Technol 61(1–4):405–420

Joshi M, More S, Singh RK, Joshi SS, Balasubramaniam R, Suri VK (2012) Experimental characterization of hydrodynamic nanopolishing of flat steel plates. Precis Eng – J Int Soc Precis Eng Nanotechnol 36(3):424–434

Strnadel B, Hlavac LM, Gembalova L (2013) Effect of steel structure on the declination angle in AWJ cutting. Int J Mach Tool Manuf 64:12–19

Wang T, Cheng HB, Chen Y, Tam H (2014) Multiplex path for magnetorheological jet polishing with vertical impinging. Appl Optics 53(10):2012–2019

Ji SM, Tang B, Tan DP, Gong B, Yuan QL, Pan Y (2010) Structured surface softness abrasive flow precision finish machining and its abrasive flow dynamic numerical analysis. Chinese J Mech Eng 46(15):178–184

Ji SM, Xiao FQ, Tan DP (2010) A new ultraprecision machining method with softness abrasive flow based on discrete phase model. Adv Mater Res 97–101:3055–3059

Yuan QL, Ji SM, Tan DP, Zhang L (2011) Analytical method for softness abrasive flow field based on low Reynolds k-epsilon model. Adv Mater Res 188:230–235

Ji SM, Zhong JQ, Tan DP, Chi YW (2012) Research of distribution and dynamic characteristic of particle group in the structural flow passage. Key Eng Mater 499:271–276

Ji SM, Xiao FQ, Tan DP (2010) Analytical method for softness abrasive flow field based on discrete phase model. Sci China – Technol 53(10):2867–2877

Ji SM, Weng XX, Tan DP (2012) Analytical method of softness abrasive two-phase flow field based on 2D model of LSM. ACTA Phys Sin 61(1):010205

Li C, Ji SM, Tan DP (2012) Study on machinability and the wall region of solid–liquid two phase softness abrasive flow. Int J Adv Manuf Technol 61(9–12):975–987

Ji SM, Qiu Y, Cai YJ, Tan DP (2014) Research on mechanism of ultrasound enhancing and the experiment based on softness abrasive flow. Chinese J Mech Eng 50(7):84–93

Chen JL, Cai YW, Xu F, Hu HG, Ai QL (2014) Analysis and optimization of the fan-pad evaporative cooling system for greenhouse based on CFD. Adv Mech Eng 712740

Tan DP, Li PY, Ji YX, Wen DH, Li C (2013) SA-ANN-based slag carry-over detection method and the embedded WME platform. IEEE T Ind Electron 60(10):4702–4713

Li X, Kagawa T (2014) Theoretical and experimental study of factors affecting the suction force of a Bernoulli gripper. J Eng Mech 140(9):04014066

Chen JL, Xu F, Tan DP, Shen Z, Zhang LB, Ai QL (2015) A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl Energ 141:106–118

Tan DP, Zhang LB (2014) A WP-based nonlinear vibration sensing method for invisible liquid steel slag detection. Sensor Actuat B – Chem 202:1257–1269

Tan DP, Ji SM, Li PY, Pan XH (2010) Development of vibration style ladle slag detection method and the key technologies. Sci China – Technol 53(9):2378–2387

Zhao LS, Wang DH, Ye J (2005) Initial study of a theoretical near-wall turbulence model. J Aerospace Power 20(2):177–181

Tan DP, Li PY, Pan XH (2009) Application of improved HMM algorithm in slag detection system. J Iron Steel Res Int 16(1):1–6

Catalano P, Amato M (2003) An evaluation of RANS turbulence modeling for aerodynamic applications. Aerospace Sci Technol 7(7):493–509

Menter FR, Kuntz M, Langtry R (2003) Ten years of industrial experience with the SST turbulence model. Turbul Heat Mass Tran 4:625–632

Qin CS, Shi YN, Feng QJ (2007) The geometrical theory for the formation of asymmetric jet (I)—the geometrical close condition. Explo Shock Waves 27(6):493–500

Qin CS, Shi YN, Feng QJ (2007) The geometrical theory for the formation of asymmetric jet (II)—asymmetrical oblique collision. Explo Shock Waves 27(6):501–508

Li X, Horie M, Kagawa T (2014) Pressure-distribution methods for estimating lifting force of a swirl gripper. IEEE-ASME T Mechatron 19(2):707–718

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, Dp., Ji, Sm. & Fu, Yz. An improved soft abrasive flow finishing method based on fluid collision theory. Int J Adv Manuf Technol 85, 1261–1274 (2016). https://doi.org/10.1007/s00170-015-8044-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-015-8044-8