Abstract

Forward slip is an important parameter often used in rolling-speed control models for tandem hot strip rolling mills. In a hot strip mill, on-line measurement of strip speed is inherently very difficult. Therefore, for the set-up of the finishing mill, a forward slip model is used to calculate the strip speed from roll circumferential velocity at each mill stand. Due to its complexity, most previous researches have used semi-empirical methods in determining values for the forward slip. Although these investigations may be useful in process design and control, they do not have a theoretical basis. In the present study, a better forward slip model has been developed, which provides for a better set-up and more precise control of the mill. Factors such as neutral point, friction coefficient, width spread, shape of deformation zone in the roll bite are incorporated into the model. Implementation of the new forward slip model for the control of a 7-stand hot strip tandem rolling mill shows significant improvement in roll speed set-up accuracy.

Similar content being viewed by others

Abbreviations

- Fi :

-

Shear force between roll and strip of the ith roll stand

- fi :

-

Forward slip of the ith roll stand

- f* i :

-

Plane-strain forward slip of the ith roll stand

- \(\bar f\) :

-

Improved value for forward slip with adjustment for width variation

- hi :

-

Exit strip thickness at the ith roll stand

- Δhi :

-

Draft of the ith roll stand

- hN i :

-

Strip thickness at the neutral point of the ith roll stand

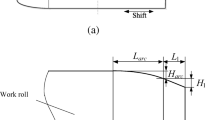

- Lp :

-

Projected contact length between the roll and the strip

- Ki :

-

ith roll adjustment factor for determining the friction coefficient

- K* i :

-

Factor for the ith roll stand used in the determination of Ki.

- Km :

-

Mill deformation resistance

- N:

-

Number of coils

- Pm :

-

Mill load

- Pi :

-

Roll force normal to roll surface for the ith roll stand

- pi :

-

Roll pressure for the ith roll stand

- Ri :

-

Radius of roll in the ith roll stand

- Tm :

-

Mill torque

- Vi,actual :

-

Actual strip speed (measured at steady-state conditions) for the ith roll stand

- Vi,error :

-

Strip speed prediction error for the ith roll stand

- Vi,predict :

-

Predicted strip speed for the ith roll stand

- vi :

-

Exit strip velocity at the ith roll stand

- v0 i :

-

Circumferential velocity of the ith roll stand

- VN i :

-

Strip velocity at the neutral point of the ith roll stand

- Wi :

-

Exit strip width at the ith roll stand

- WN i :

-

Strip width at the neutral point of the ith roll stand

- x:

-

Horizontal position in deformation region

- αi :

-

Bite angle of the ith roll stand

- βi :

-

Neutral angle of the ith roll stand

- γi :

-

Plane-strain prediction accuracy parameter for the ith roll stand

- θ:

-

Angular position in deformation region

- μi :

-

Friction coefficient between the roll and the strip of the ith roll stand

- μ* i :

-

Parameter based on torque, load and roll radius which reflects friction conditions in plane strain

- Фi :

-

Parameter to account for width changes during deformation in the ith roll stand

References

Bakhtinov, Yu. B., 1988, “Forward and Backward Slip during Rolling,”Steel in the USSR, Vol. 18, pp. 364–367.

Hum, B., 1996, “Measurements of Friction during Hot Rolling of Aluminum Strip,”Journal of Materials Processing Technology, Vol. 60, pp. 331–338.

Koncewicz, S., 1991, “Investigation on the Forward-slip and the Neutral Angle in Flat Rolling,”Archives of Metallurgy, Vol. 36, pp. 115–130.

Lee, W. H., 2002, “Mathematical Model for Cold Rolling and Temper Rolling Process of Thin Steel Strip,”KSME International Journal, Vol. 10, pp. 1296–1302.

Lenard, J. G., 1997,” A Study of Friction during the Lubricated Cold Rolling of an Aluminum Alloy,”Journal of Materials Processing Technology, Vol. 72, pp. 293–301.

Seregin, S.A., 1989, “Relation Between Forward Slip and Spread in Rolling,”Steel in the USSR, Vol. 19, pp. 438–440.

Zhang, W., 1995, “Determination of Forward Slip in H-Beam Rolling,”Journal of Materials Processing Technology, Vol. 54. pp. 114–119.

Zhang, Y., 1989, “Research on the Forward Slip Model in a Universal H-Beam Mill,”Steel Iron, Vol. 11, pp. 39–41.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moon, Y.H., Jo, I.S. & Van Tyne, C.J. Control Scheme Using Forward Slip for a Multi-stand Hot Strip Rolling Mill. KSME International Journal 18, 972–978 (2004). https://doi.org/10.1007/BF02990869

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02990869